KRONE VariPack Pro – Throughput and density in perfect harmony!

Thanks to the three endless belts, the individually adjustable bale density on the terminal and the very fast bale ejection, the high-performance baler is an efficient machine for forage harvesting.

- EasyFlow and a minimum of moving parts

- Integral Rotor for maximum throughputs

- Precision cutting system for smooth and precise cuts

- Automatic cleaning of belts and guide rollers – Two cleaning rollers

- Two drives for reliable bale starts and perfect shapes

- Roll chute is standard for easy net refills

- Auto controlled rear door and stroke end cushioned ram for fast unloading cycles

- Automatic grease applicator and oil lubricator

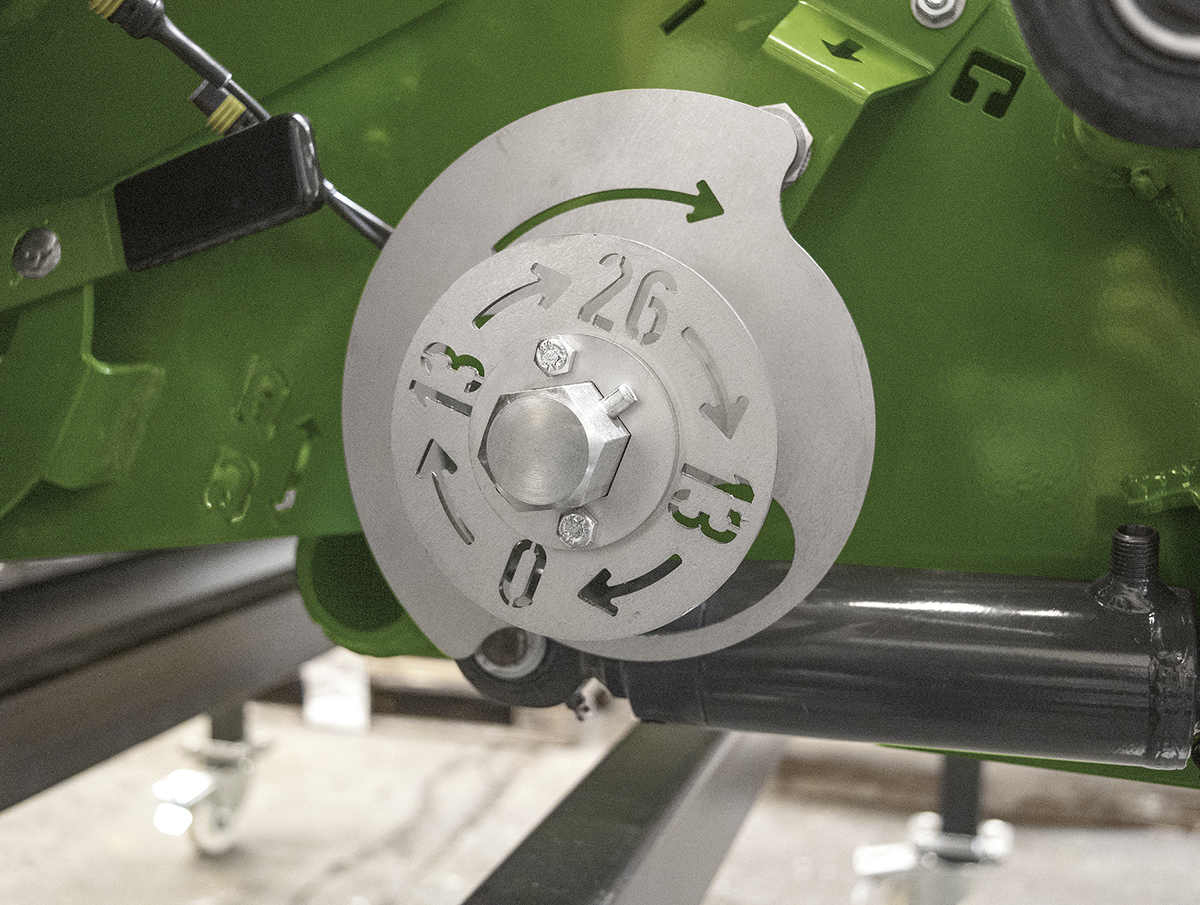

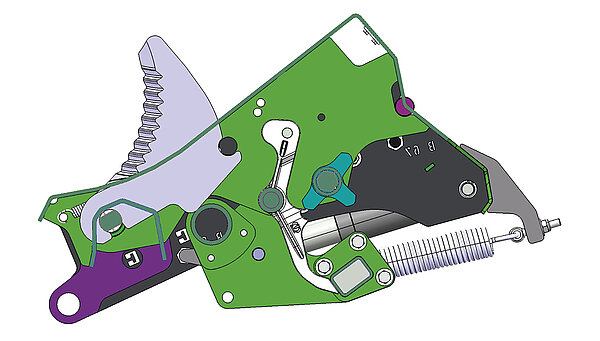

The blade group

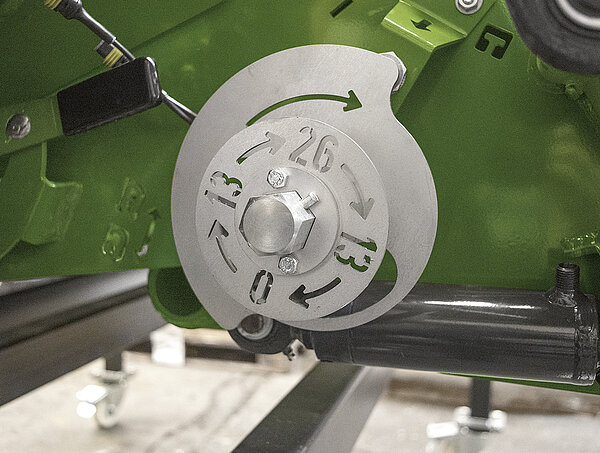

KRONE VariPack V 165 XC Pro and V 190 XC Pro have a 26-blade cutting system that can be selected in groups of 0, 13, 13, or 26 blades to give cutting lengths of 84 mm or 42 mm. The change is made fast and simple for easy adjustment to varying conditions. Also, the option of using the same number of blades in two different groups allows you to use sharp blades all day long – also throughout very long working days. Before a group of blades is selected, the selector shaft makes a 360° revolution which removes the debris in this area ensuring continued precision control of each individual blade.

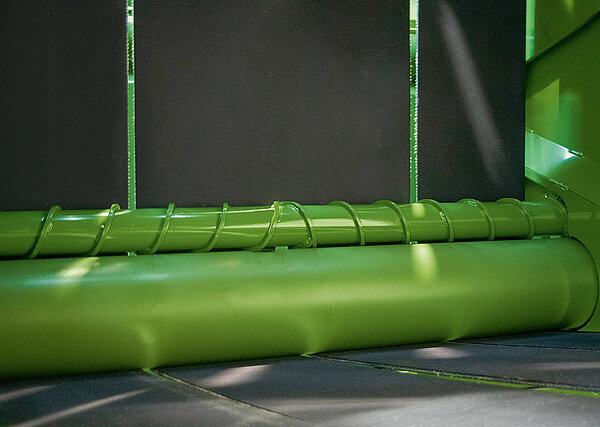

The KRONE bale chamber

The VariPack Pro chamber is made up of three endless belts that feature a smooth surface. This design makes VariPack the specialist baler for dry material such as straw, hay and haylage. The belts are constantly cleaned by two rollers so they can reliably keep up their good work. The soft core kit allows you to produce bales for specific applications.

Product features

The EasyFlow pick-up rides on two castering gauge wheels that pivot flexibly for smooth tracking in all curves without scuffing. The working height of the pick-up is set without tools in a hole pattern.

The crop press roller supports the work of the pick-up by detecting the size of the swath and preparing it for effective gathering. The height is altered on a simple mechanism for easy and fast use and adaptation to varying crops, swath volumes and work rates. This results in clean and thorough gathering.

Measuring 6 mm in diameter and mounted with large coils, the tines are particularly vigorous and hard-wearing. Narrowly spaced at 55 mm, they pick up also short haulmed and heavy crops thoroughly and without contamination.

KRONE had good reasons for opting against cam track controlled tines on the EasyFlow pick-up. Instead of using many moving parts that are prone to wear, EasyFlow has special strippers that ensure the tine angle is always right the length ideal.

The EasyFlow pick-up offers a 2.15 m work width for high hourly outputs. With its 6 mm thick double tines, it picks up even the widest swaths and feeds the material in a consistent flow to the rotor cutter. Pivoting and spring-loaded, EasyFlow provides perfect ground contouring even in the roughest terrain.

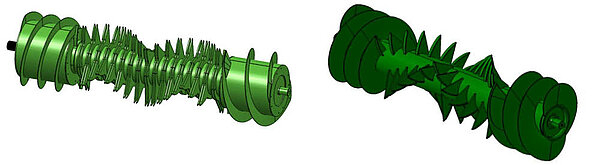

The double tines pull the material in a consistent flow through the blades, preventing any haulm to slip through and leading to higher bale weights, because cut material is baled to higher densities. The helix ensures there is no peak load in the cutting system for smooth operation and quiet running. At the same time, the chevron-line of tines on the pick-up supplies the material in a consistent flow to the cutting system for an optimum throughput and uniform bale fills.

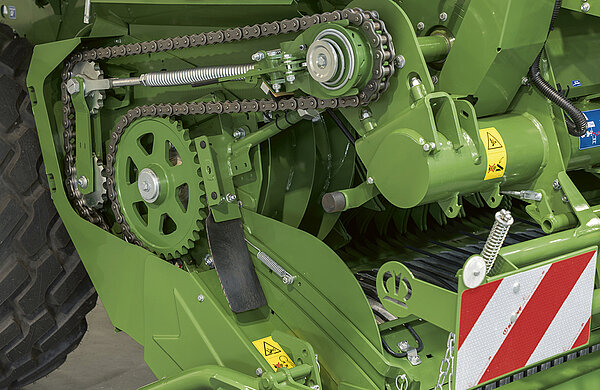

The pick-up and the Integral Rotor are driven by a 1 ¼inch chain. The simple and robust drive uses only few moving parts and makes for easy servicing and reduced wear.

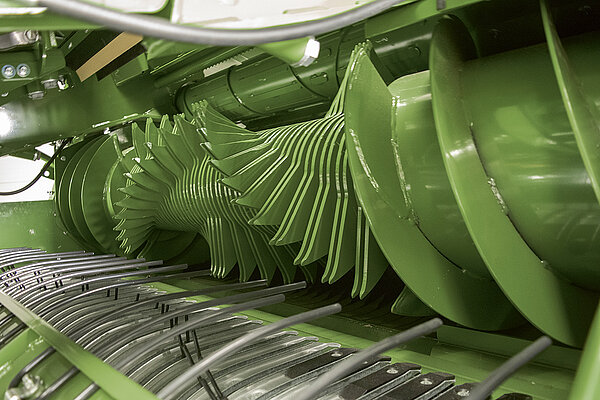

Integrating the feed rollers in the rotor leads to a very consistent and dependable feed of material from the pick-up to the rotor – another boon for the overall crop flow and reliable machine performance.

VariPack has the feed auger integrated in both ends of the rotor cutter (left) and the feed rotor (right). This means that only one drive is required to power the pick-up and the rotor. Combining helical tines and augers on the same rotor optimises the material flow across the entire width of the rotor for high bale weights and perfect cuts. To minimise wear, the cutting rotor is made of Hardox.

The individual blades are operated hydraulically. This ensures accurate control as they move into and out of the crop flow and is just another detail to optimize the overall performance of the machine.

The operator selects a group of blades and activates it hydraulically from the convenience of the cab.

Die KRONE VariPack V 165 XC Pro und V 190 XC Pro verfügen über ein Schneidwerk mit 26 Messern. Die Gruppenschaltung erlaubt den Einsatz von 0/13/13 oder 26 Messern. Somit kann die Schnittlänge von 84 bzw. 42 mm schnell und einfach an die jeweiligen Auftragsbedingungen angepasst werden. Ebenfalls kann durch den Einsatz mehrerer Messergruppen sichergestellt werden, dass auch an langen Arbeitstagen stets mit scharfen Messern geschnitten wird. Beim Wechsel der Messergruppen wird zunächst immer eine 360°-Drehung der Schaltwelle durchgeführt. Dies entfernt den Schmutz aus diesem Bereich und sorgt für eine zuverlässige Funktion der Einzelmessersicherung.

Each blade is spring-loaded for individual protection against damage. Whenever it is hit by an object it retracts from the crop flow and automatically returns into working position after the object has passed. The other blades remain unaffected by this and continue cutting, ensuring a consistent quality of cut.

To fit or remove the blades, simply lower the blade cassette. To unlock the blades, all blade levers of the single blade locking device are swivelled away simultaneously. Last, remove the blades conveniently from above.

VariPack Pro has two cleaning rollers These clean the belts and the guide rolls, ensuring a consistent powerflow to the belts. One of the two cleaning roller is powered to warrant optimal performance.

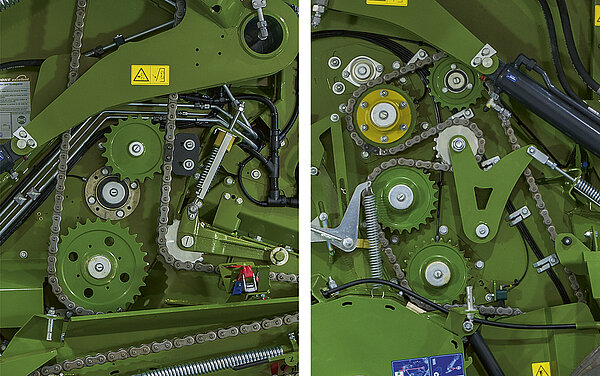

The belt rolls are driven by two drive rollers to ensure an absolutely dependable bale start. The main drive is powered from the right machine side, the second drive is powered from the left machine side.

The rolls are spaced in close vicinity so they transfer the drive power reliably to the belts. This in turn makes for reliable bale starts and continued roll in the filled chamber.

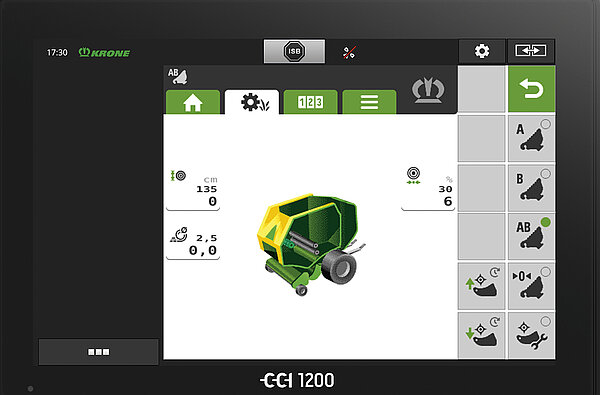

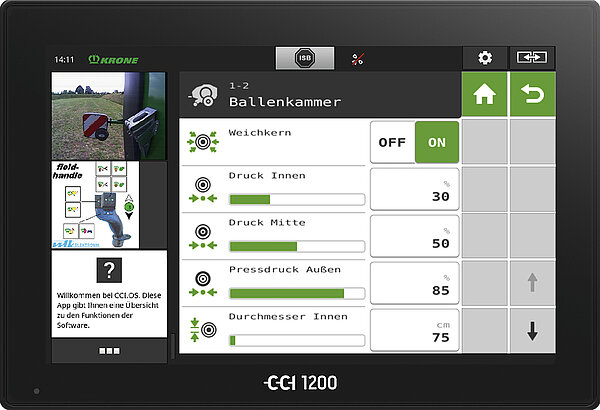

With the VariPack Pro, the baling density can be infinitely adjusted in three zones directly from the terminal. The belt tension can be used to achieve different baling pressures in the various bale areas. This ensures that the bales are optimally baled for their intended use – for example, with maximum density for long transport distances or with a soft core for subsequent drying.

The VariPack Pro model range is designed to deliver various bale diameters. VariPack V 165 (XC) Pro produces 0.80-1.65 m diameter bales. VariPack V 190 (XC) Pro churns out 0.80-1.90 m diameters. This way you can tailor the size of the bales to individual customer applications, for example feeding or drying.

There is room to store one roll of net wrap on each side of the machine. This gives you plenty of net supply that keeps you going during long working days.

The fresh roll slides down the chute and into the cradle. It couldn’t be easier for operators. Then the net is threaded into the chamber, which is equally easy thanks to the rigid net feeder. Next, run the net over the swing and into the chamber.This again is made easier after the upstream roller disappeared here.

Net or twine refills are very easy. Simply fold out the chute on the left hand side and slide the fresh roll into the cradle. You no longer lift the heavy roll into the cradle.

The cradle lowers for convenient replacement of the net roll. Arranged at a low height, it is readily accessible from one of the two steps.

The optional bale clamp can be used to hold the bale securely on slopes. The clamp can be closed using an additional control unit and the bale is collected after the tailgate is opened. When the bale is secure, the clamp can be opened again.

Keeping halts as short as possible is critical for high productivity in round baling. Therefore unloading the bale effectively and fast is the key feature of the bale ejector. At the same time, the ejector is designed to give optimum access to the blades.

To reduce the time the tractor spends waiting for the bale to leave the chamber, the hydraulic cylinders have stroke end cushioning which allows them to operate the door fast. Minimum downtime translates into maximum throughputs after all. At the same time, end of stroke cushioning slows down the door as it closes and therefore reduces machine wear.

The rear door and the net wrapping cycle are controlled automatically so all tying/wrapping is optimized to minimize downtime and maximize throughputs.

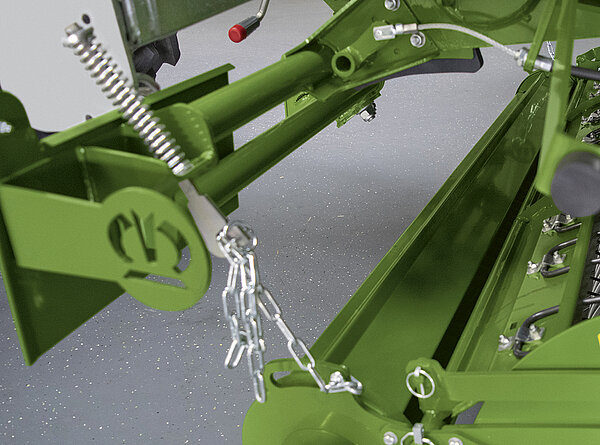

An 80 ball hitch is also available for VariPack Pro for bottom attachment. This warrants smoothest rides, better manoeuvrability and minimum wear.

VariPack Pro has a standard 40 mm hitch ring for bottom- or top-mount attachment. A notch system adjusts the drawbar quickly to the required attachment height. In addition, three more hitch options are available to suit various needs in specific countries.

Three different tyre options are available for VariPack Pro: 500/55-20 12 PR, 500/60 R 22.5 and 600/50 R 22.5. The air brake is a standard feature.

All VariPack Pro models have load sensing as a standard feature which reduces the number of hydraulic lines that need coupling. Load sensing also saves tractor power, because the pump supplies the remotes only on demand. In addition, the feature allows operators to select multiple functions from the terminal and the convenience of the cab.

A camera monitors the machine assemblies and the immediate surroundings of the VariPack, thereby improving both operator comfort and road safety. Can be ideally combined with the CCI terminals or the 7" monitor – to ensure perfect control in every situation

The moisture sensor sends material data to the cab so you know exactly the quality of the material you are harvesting so spoilage and moulding is no issue.

This package adds comfort and includes LED work lights for all service and maintenance points plus reflective strips under the panels and also rear lights. These lights are a boon when changing net rolls and cleaning the machine at night. Also, they improve visibility around the machine as well as general safety in the field.

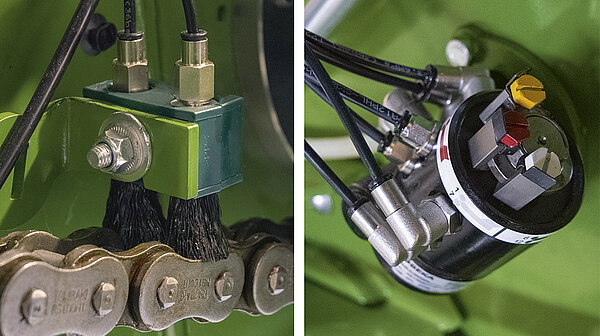

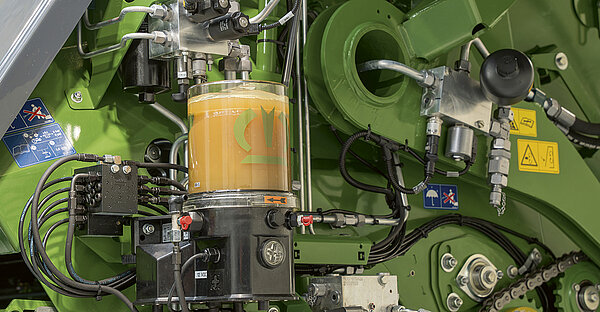

The bearings that are built into VariPack Pro are heavy duty and have special seals which are lubricated automatically for maximum service life.

The drive chain is lubricated automatically for quiet running and long service life. The easy-adjust piston pump allows you to apply the proper attention to each chain.

VariPack Pro has an auto lubricator that minimizes servicing and maximizes machine life.

This dog clutch on the right machine side can cut the power flow to the intake system which stops rotating so you can finish a bale despite a blockage in the intake system. At the same time, the rotor revolves freely to give ready access to the blades.

VariPack Pro has a mechanical stand as a standard feature. This makes for safe stability when parked. The two-speed gearbox on the stand is easy to operate for low-effort and fast control. It can swing to the side to provide generous ground clearance when harvesting high-volume swaths.

The two steps on the front give convenient access to the net/twine unit. Swapping net rolls as well as cleaning and servicing is easy and convenient now.

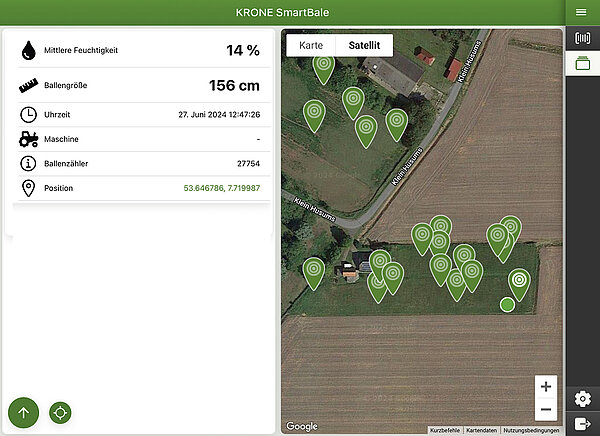

KRONE SmartBale displays all deposited round and square bales on a bale map. Depending on the baler equipment, the SmartBale app provides additional information such as moisture, weight, dimensions and whether the crops have been cut. Moist bales are colour-coded so that they can be easily identified and stored separately.

TIM (Tractor Implement Management) is an option that allows your machine to communicate with the tractor and control it. This means the baler automatically stops the tractor to start the tying cycle, opens the rear door when tying is completed and closes the door after the bale has been deposited. TIM reduces operator fatigue, downtime, fuel consumption and leads to more uniform bales and boosted productivity.

You can also use the terminal on your ISOBUS compatible tractors to operate the VariPack Pro. If your tractor has an ISOBUS terminal, you won’t need an extra terminal in the cab.

The CCI 800 and CCI 1200 operator terminals are equipped with large 8" or 12" colour displays with touch function which display the machine controls and camera footage side by side on the same screen. Both terminals are ISOBUS-compatible and therefore prepared for use with other machines.

The DS 500 terminal has a user-friendly 5.7inch touch screen, twelve keys and a dial on the back. The unit can be used for VariPack Pro but also for other KRONE machines.

The right model for every field of use

| VariPack V 165 Pro | VariPack V 165 XC Pro | VariPack V 190 Pro | VariPack V 190 XC Pro | ||

|---|---|---|---|---|---|

| Bale dimensions (m, Ø x w) | 0.80 - 1.65 x 1.20 | 0.80 - 1.65 x 1.20 | 0.80 - 1.90 x 1.20 | 0.80 - 1.90 x 1.20 |

configure

|

| Bale Chamber | variable | variable | variable | variable |

configure

|

| Machine dimensions (m, l x w x h) | 4.90 x 2.74 x 2.98 | 4.90 x 2.75 x 2.98 | 4.90 x 2.75 x 3.05 | 4.90 x 2.75 x 3.05 |

configure

|

| Pick-up working width (m) | 2.12 | 2.15 | 2.15 | 2.15 |

configure

|

| Power requirement kW/hp | 74 / 100 | 74 / 100 | 74 / 100 | 74 / 100 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

VariPack Pro

Rundballenpressen

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)