RX is KRONE’s latest generation of forage wagons. Offering capacities between 47 and 56.2 yd³, these machines serve two purposes – as self-loading and as controlled-unloading forage wagons but also as silage trailers in the transport fleet serving the forage harvester. The optional 30.5-inch tires offer a higher load bearing, easier pulling, better soil protection and enhanced road safety. This versatility is paired with an outstanding reliability and efficiency, making the RX a particularly productive machine.

- Articulated drawbar for high ground clearance

- Drawbar suspension for comfortable rides

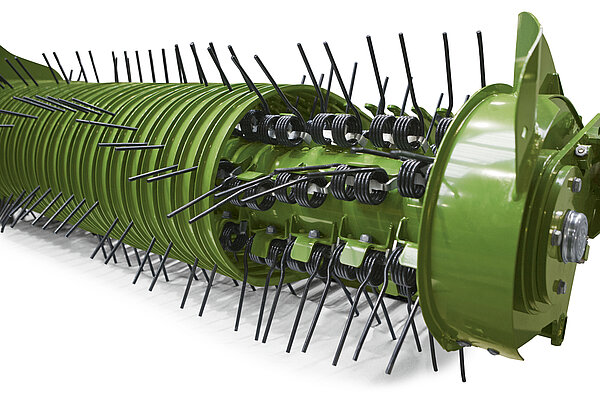

- Camless pick-up, W-arrangement of tines

- Swing-out cutterbar with 46 selectable knives

- Massive cut-and-feed rotor with wide Hardox tine plates

- Greater capacity from pivoting headboard

- Double chain-and-slat floor slopes at front

- Steel structure and steel floor

Product video

KRONE RX – Self-loading and harvester-filled forage wagon

Offering capacities between 47 and 56.2 yd³ (DIN 11741), these wagons are not only self-loading but can control the unloading rate and serve as silage trailers in support of the forage harvester. This versatility is paired with an outstanding reliability and efficiency, making the RX a particularly productive machine.

Product features

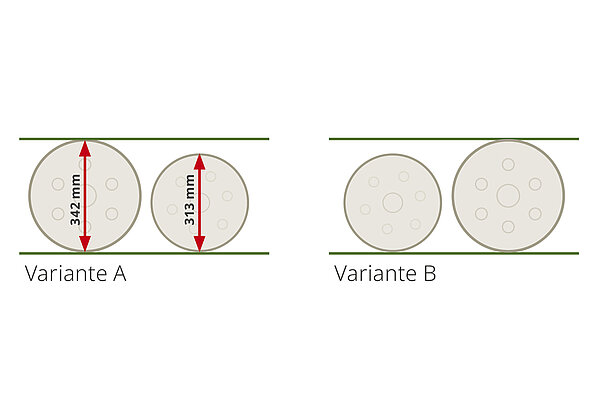

The RX 330 and 370 models are equipped with a compound running gear as standard. As an option, a hydraulic running gear is available, which is the standard for model RX 400. Both running gear variants offer a perfect combination of stability, agility and convenience. The even weight distribution ensures easy handling on uneven terrain, while precise control and high reliability ensure maximum efficiency.

A nitrogen damper provides electro-hydraulic suspension for the pick-up for even better soil protection. The system allows operators to set the suspension pressure from the cab and on the move.

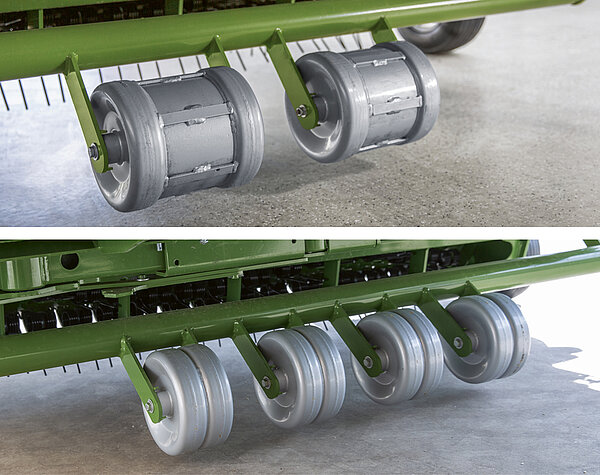

Wide guide wheels behind the pick-up ensure clean forage intake on damp ground. The height-adjustable wheels prevent them from sinking too deep and therefore protect them from damage. The 28 mm OptiGrass cutting unit has four wheels, the 37 mm cutting unit has two.

The articulated drawbar with double-acting ram is standard specification and provides a generous ground clearance of up to 75 cm – enough to roll on clamps no problem. The new automatic articulated drawbar offers a better ground clearance for headland turns. One headland and one road position can be programmed to the control unit.

In undulating terrain, the pick-up oscillates through a constant range around the core of the cutting rotor, maintaining an optimum flow of material into the machine no matter how difficult the conditions. The steering is aligned with the centre of the cutting rotor, enabling a wide lift height – ideal on the headland.

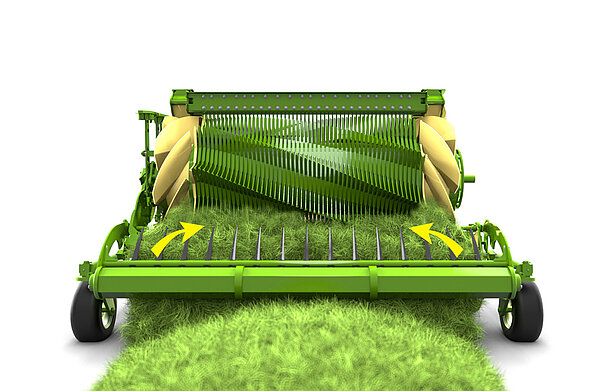

The laterally pivoting pick-up follows ground contours both axially and transversely and benefits from more generous travel now – courtesy of the integral hydro motor that replaces an external sprocket. The result is a clean rake and nothing is left behind.

The pneumatic guide wheels on either side of the pick-up offer height control for full adaptation to any ground contours. Tracking excellently behind the tractor during headland turns, these wheels avoid scuffing and offer best protection of the sward.

The 6.5 mm tines with large-diameter coils withstand the most arduous conditions.

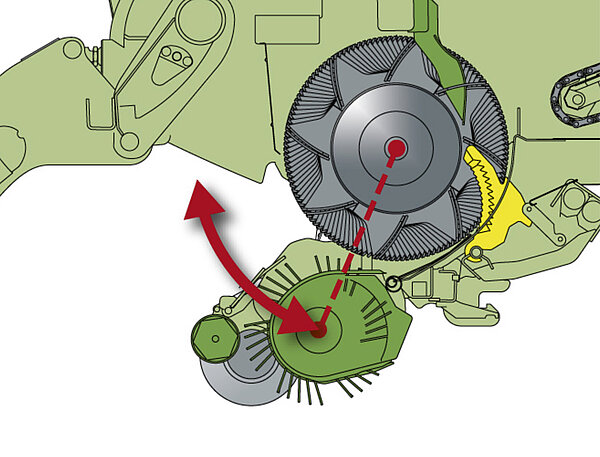

The integral hydro motor offers a number ofadvantages:It frees space on the pick-up ends for a wider work width, maintenance-free, the absence of sprockets on the sides translates into a larger pivoting range, adaptation to the respective harvesting conditions by manually or automatically adjusting the speed via ISOBUS, depending on the driving speed

Arranged in a W, the tines warrant a consistent crop flow and an equally consistent and fullwidth supply of the material to the rotor cutter, boosting throughputs and machine fills.

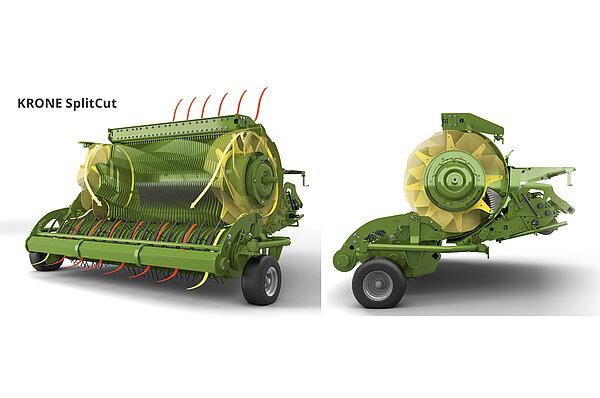

A concept which, thanks to its innovative design, enables optimum conditioning of the forage across the entire width of the rotor. Consisting of a cutting blade, a divider wall, scraper tines and crop deflector sheet, the two SplitCutters ensure that the crop is separated at the cutting blade and fed back centrally into the crop flow. This ensures that every stalk has completely passed through the cutting blades, resulting in perfect conditioning quality.

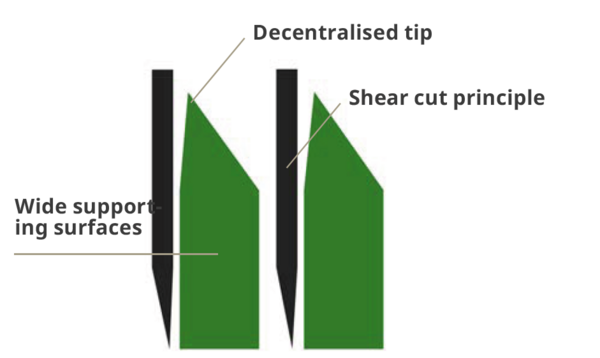

Precise shear cutting is made possible by the use of extrawide steel plates in combination with a dense arrangement of blades and supporting surfaces. The width of the supporting surfaces varies between 17 mm and 22 mm, depending on the cutting unit. The decentralised arrangement of the tips of the supporting surfaces creates an optimum shearing effect on the blade, resulting in the crop being picked up gently and with little effort. This prevents mushing.

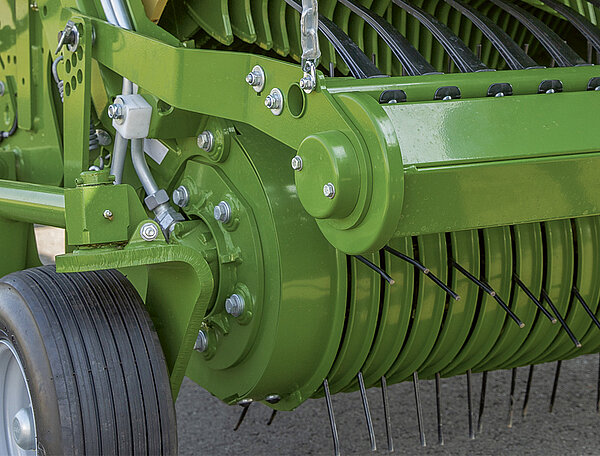

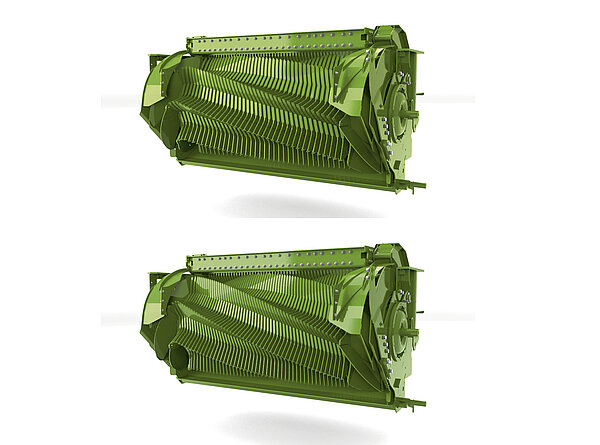

The new integral rotor concept combines numerous advantages and significantly improves the performance of the cutting system. The 22 cm wide auger bodies, which are part of the cutting rotor, ensure that the crop is transported evenly and cleanly to the centre of the rotor. This results in a powerful crop flow with maximum pick-up width and, at the same time, the best possible cutting quality thanks to optimum pre-compression in the conveyor pockets. The concept, in conjunction with the enormous diameter of the cutting rotor, enables the RX to achieve maximum throughput with optimum conditioning quality. 1. The entire swath is picked up via the wide pick-up 2. The auger body conveys the grass from the outer areas to the centre of the rotor. 3. The material is compacted in the rotor pockets and formed into a perfect cut package.

Maximum throughput rates and high loading speeds allow hardly any errors. In practice, however, uneven swaths with changing crops are more common. Thanks to the powerful KRONE Powerbelt, these short-term load peaks are cushioned and the overload protection is prevented from tripping. With the KRONE Powerbelt you can drive on while others stand still.

The KRONE Powerbelt drive concept supports the rotational speed reduction from the main drive to the cutting rotor by means of a planetary gearbox located in the rotor. The compact design of the assembly allows us to maximize the length of the rotor and hence the width of the crop flow. The drive is impressive thanks to its high throughput, extremely quiet running, low wear and minimal maintenance. A wide belt enables power transmission of up to 430 hp in the drive train. A cam clutch in the main universal shaft ensures the safety of the entire drive train up to a torque of 3000 Nm.

With the OptiGrass system, the RX series offers two cutting unit variants with theoretical cutting lengths of 28 or 37 mm. The integral rotor concept, which cuts more precisely and shorter than ever with fewer blades, ensures compact cut packages. Combined with the EasyFlow pick-up, the Opti-Grass cutting rotor and SpliCut edge-cutting system, the KRONE RX delivers an optimum result in all conditions.

The new high-performance 'OptiGrass' cutting unit systems take forage quality to a new level. In addition to a theoretical cutting length of 37 mm with a maximum of 40 blades, it is now possible to achieve a cutting length of 28 mm with a maximum of 54 blades. Together with the KRONE SplitCut, nothing stands in the way of optimum forage recovery. With the optionally available SpeedSharp blade grinding device, sharp blades are guaranteed everywhere and at all times!

The desired cutting length can be set quickly and easily via the central blade group control system. With the ZX, theoretical cutting lengths of 28 or 56 mm with 54 blades and 37 or 74 mm with 40 blades can be achieved. In the zero position, the crop remains uncut.

Equipped with individual spring protection, each blade retracts and swings back automatically once the foregn object has passed. The tripping force is set variably from the cab and can be adjusted to special conditions.

The blade cassette lowers hydraulically to remove a blockage. After the blockage has been removed, the blade cassette is swivelled in again and work can be resumed immediately.

The crop cannot escape the blades because the distance between the blade and the wide supporting surface of the conveyor rotor tine and its asymmetrical tip is very small. The result: perfect cutting quality through and through, no squeezing, no mushing.

Cutting with their full edges, these blades lead to smoother and quieter running. The wavy blades maintain their sharpness over extended periods of time.

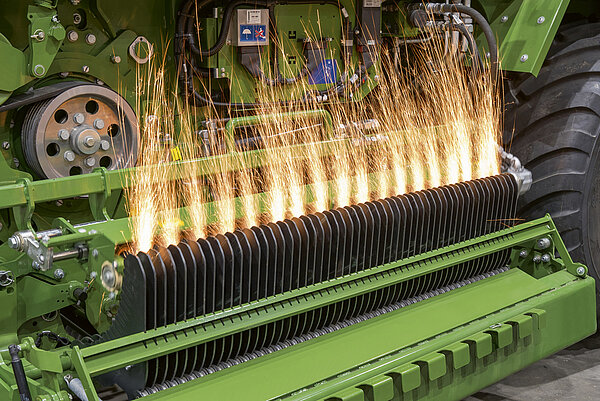

Simply swing out the blade cassette, fold up the grinding shaft, couple two oil hoses and connect an electric lead. Then press an external control to start grinding hydraulically and watch how the shaft moves automatically up and down and to the sides, completing the job without any interference from the operator. The grinding is carried out with the blade cassette out and alongside the machine so you can easily watch the process.

A complete grinding process, including swivelling the cutting unit out and in, is quickly completed: In just five minutes, all 40 or 54 blades are sharp, depending on the number of grinding cycles. With the blade cassette out and alongside the machine, the operator can watch the grinding process and conveniently check on the result.

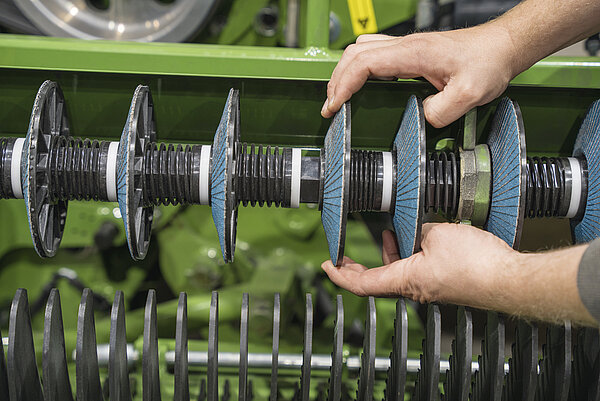

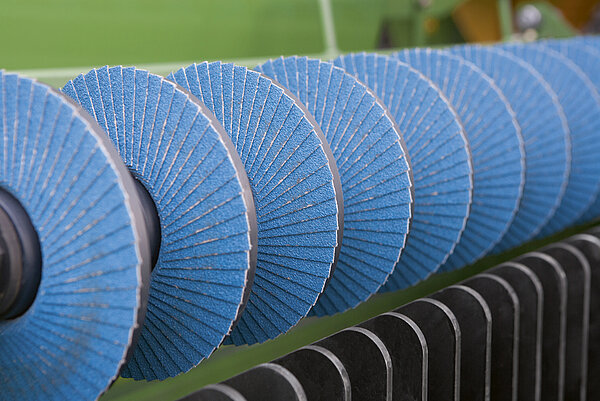

Each disc is pressed on to the blade by a bevel spring, a design that leads to a high-quality and consistent cut of all blades whilst minimising the material that is removed from each blade. The system warrants consistently sharp blades even when these show different degrees of wear.

Depending on the number of blades, grinding is carried out with 18 or 20 flap discs which, with individual, widely overlapping grinding flaps, ensure a particularly high grinding performance and a long service life. give a 'cold' grind that prevents the blades from annealing.

The grinding discs of the optional fully automatic grinding device are arranged on a laterally movable and hydraulically driven shaft. All work processes for grinding the blades are carried out automatically at the touch of a button.

They can set the blade grinding interval on the terminal to adapt the intensity to the actual level of wear.

The optional cross conveyor belt is an ideal feature for farmers who feed the fresh forage directly to their cows. The 90 cm wide conveyor belt unloads the forage on both sides of the forage table. But you can also empty the machine as usual via the discharge rollers without any previous modification. The cross conveyor belt connected to the backpack tailgate swivels upwards when opening together with the tailgate. An additional, double-acting control unit is required to operate the cross conveyor belt.

The particularly robust gearboxes and 1 inch thick roller chains with automatic chain tensioners transmit the full power. The chains are powered by a shaft that runs down the chassis, driving a right-angle gearbox inside one of axial section beams.

Specify your forage wagon with three enclosed rollers and an adjustable tailboard and you can produce even more uniform mats. Studded with V-tines, the rotors spread the crop across the full machine width, with the rotors spinning at a higher rpm to cut down on unloading time.

Four powerful LED light strips are fitted as standard in the loading space to facilitate working in the dark. With its two working lights at the rear, the KRONE RX provides optimum illumination of the surrounding area. For ideal illumination of any working environment, two additional freely positionable working lights can be mounted at the front or rear. The cable position required for this is prepared as standard in the RX to enable simple and quick assembly. Two modes can be used to conveniently configure field and discharge lighting.

An LED strip located under the side guard provides optimum illumination of the drive components and the swung-out blade cassette. In addition, the lighting of the feed channel ensures straightforward handling when swivelling the blade cassette in and out.

Two LED strips on both sides provide optimal lighting in the area of the crop intake. They provide sufficient illumination in front of and behind the pick-up and, thanks to their diffuse light, create a pleasant working atmosphere without dazzling.

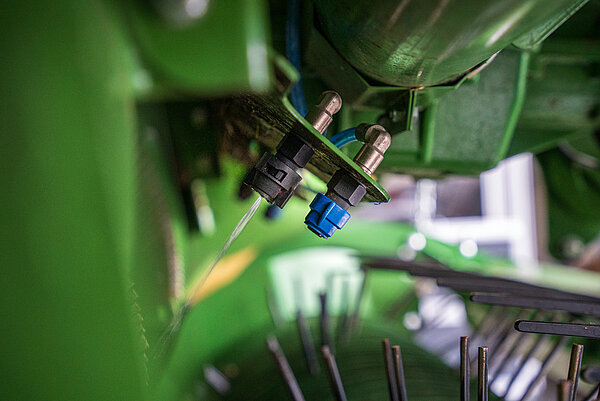

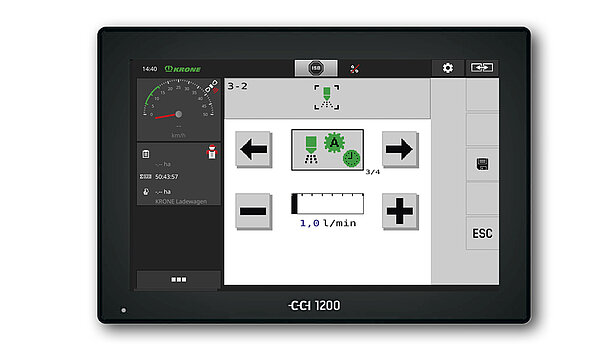

The dosing system is fully integrated into the user interface of the RX and can be operated in different modes. Whether a fixed dosing rate (l/min), a dosing rate-dependent dosing rate (an optional weighing device is required for this) or a percentage flow rate – all values can be set easily and conveniently in the submenu.

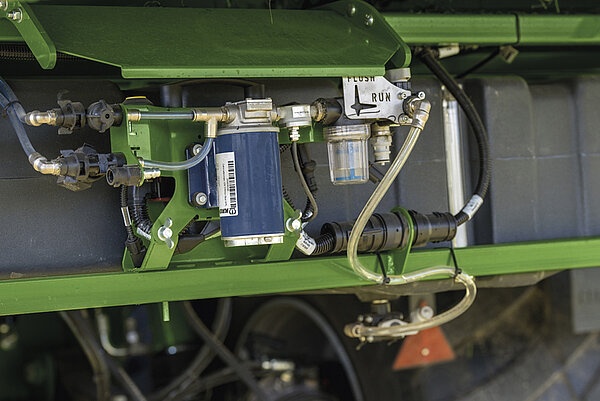

The pump unit, which includes filters and valves, is installed in the rear of the vehicle to save space. It can be easily removed without tools, for example to protect it from frost in winter. Practical functions, such as a compressed air connection for emptying the lines, have also been considered. To carry out maintenance work, the pump can be switched by a push button.

The KRONE RX features a 200-litre silage additives tank which is optimally positioned for access behind the rear of the vehicle. Thanks to two side openings, the tank is easy to clean. The electronic filling level indicator on the terminal enables quick and precise monitoring of the filling level at any time.

The electronic weighing system uses sensor pins inside the drawbar and on the tandem/tridem axle with hydraulic levelling. The system determines the weight of the load by computing the difference between the gross weight and the weight ofthe material left on the machine after unloading is completed.

The ZX can be optionally equipped with the KRONE Smart-Connect telemetry unit. This interface is used with GPS and WLAN function as the basis for data management. Telemetrics allow managers to track the wagon and record all major data and transmit them to the office. This is the modern way of farming.

The KRONE loading and forage transport wagons can optionally be fitted with a camera in the loading space and a rear-view camera. The high-resolution images increase the field of view, make it easier to work and increase safety levels especially when shunting, loading and unloading. Can be ideally combined with the CCI terminals or the 7" monitor – to ensure perfect control in every situation.

The covers are operated by hydraulic motors for quick and dependable control.

When the loading space cover halves are folded down to the side, the ZX is easy to load from the forage harvester. There is nothing in the way that might obstruct filling.

The optional crop covers are flexible to adapt to the contours of the forage mass. Hinged to the sides, they cover the material effectively and will not open as the combination travels at speed.

The user interface of the KRONE RX is particularly user-friendly thanks to its simple and intuitive operation. Various work steps are illustrated by visualisation, such as rotating discharge rollers. More comfort is provided by the configurable display bar which can be used to individually adjust the user interface to the user's requirements. Automatic functions, such as the PowerLoad automatic loading system, the automatic unloading system and the drawbar control system, are also available. The new visual filling level indicator above the loading space ensures the best possible throughput rate.

The two operator terminals CCI 800 and 1200 with 8″ or 12″ touch display allow users to split the screen for example to see all machine control elements in one view and the camera footage in the other. Also, an additional AUX joystick enhances operator comfort even further.

The compact DS 500 terminal has a 5.7-inch colour display screen can be operated with 12 function keys, the touchscreen or the scroll wheel on the back. An optional joystick is available for even more convenient operation.

The right model for every field of use

| RX 330 GL | RX 330 GD | RX 370 GL | RX 370 GD | RX 400 GL | RX 400 GD | ||

|---|---|---|---|---|---|---|---|

| Type | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon | loading and forage wagon |

configure

|

| Capacity (m³) | 33 | 33 | 37 | 37 | 40 | 40 |

configure

|

| Pick-up working width (m) | 2.12 | 2.12 | 2.12 | 2.12 | 2.12 | 2.12 |

configure

|

| Cutting length (mm) with 54 blades | 28 | 28 | 28 | 28 | 28 | 28 |

configure

|

| No. of discharge rollers | none | 3 (2) | none | 3 (2) | none | 3 (2) |

configure

|

| Power requirement kW/hp | 130 / 175 | 130 / 175 | 130 / 175 | 130 / 175 | 130 / 175 | 130 / 175 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN (US):]](/fileadmin/_processed_/7/3/csm_AK_08553_205939_d22f1b8a32.jpg)

![[Translate to EN (US):]](/fileadmin/_processed_/c/f/csm_DJI_0725_233408_0107815f4f.jpg)

![[Translate to EN (US):]](/fileadmin/_processed_/6/0/csm__AK_8603_235368_25d6669381.jpg)