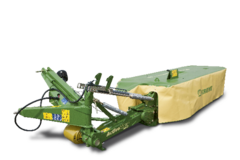

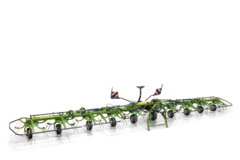

The EasyCut F model range is a line-up of innovative front mowers with or without tine or roller conditioner and work widths of 8'10.8" to 12' 3". At the same time, the range comprises particularly compact and light-weight front mowers for mountain fields and applications. Top hats are available for some models. These form narrow swaths that the tractor can straddle.

NEW: The fourth generation of the EasyCut F 320 and F 360

Agritechnica 2025

With the fourth generation of the EasyCut F 320 and F 360, KRONE presents two new front mounted mowers without conditioners that can be customised thanks to the modular design and three attachment options to meet individual operational requirements.

Read the news

Product video

KRONE EasyCut F – Front-mounted disc mowers

The EasyCut F series includes innovative front mowers with working widths from 8' 10.8" to 11' 9.6", with optional tine or roller conditioner. The EasyCut M front mowers are our lightweight machines designed for operation on steep slopes and for spreading material across the work width. Their hitch points are configured to attach as well to small tractors for special applications.

Product features

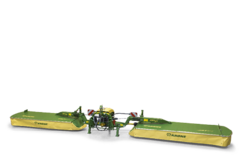

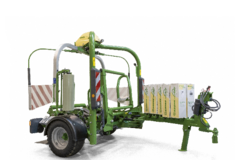

The merger auger of KRONE's EasyCut F 400 Fold mower offers multiple advantages for forage harvesting: variable swath width, maximum forage quality and strip-free mowing thanks to great overlap. Combining it with other mower, e.g. the EasyCut B or EasyCut R models, allows for maximum overlap when driving around curves and working on slopes.

KRONE's innovative EasyCut F 400 Fold with merger auger sets new standards in forage harvesting. Depositing evenly formed swaths, the mower allows for efficient crop harvesting. A working width of more than four metres guarantees maximum efficiency – with a transport width of three metres made possible by the patented foldable cutterbar. Thus ensures excellent manoeuvrability for example when driving through cramped gates or unloading unto narrow forage tables.

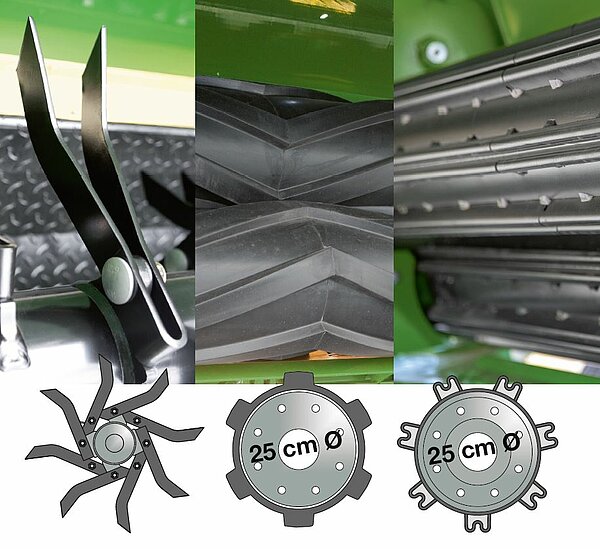

The EasyCut F 400 CV Fold conditioner is equipped with durable V-shaped steel tines of robust design. The hard-wearing V-shaped steel tines can move out of the way of obstacles to reduce wear.

Dairy farmers are looking into the potential of fresh grass for increasing milk yields from the basic ration. In view of rising silage storage costs, hay milk production programmes and further aspects fresh mass is being viewed from a different angle today. This new approach is supported by KRONE who offers the ideal machines that help you cut and feed highly valuable fodder every day. Combining the EasyCut F 400 CV Fold mower with the MX 330 GD forage wagon makes a powerful punch.

The foldable cutterbar of the KRONE EasyCut F 400 Fold makes working in cramped locations with bad visibility easier. Its transport width of less than 3 m ensures perfect handling, particularly when depositing the forage on narrow tables.

Immediately after depositing, the loading and forage transport wagon picks up the swaths cleanly and evenly before placing them loss-free on the forage table via the cross conveyor belt available ex works.

The merger auger deposits the crops in a compact, evenly shaped swath. This not only provided for quick, efficient harvesting but also ensures improved forage quality.

The perfect combination of KRONE machines: The EasyCut F 400 Fold front mounted mower with merger auger and the loading and forage transport wagon RX with 40 m3 loading volume constitute the KRONE Fresh Matter-Express, which stands for maximum efficiency and unsurpassed forage quality.

The right model for every field of use

| EasyCut F 280 | EasyCut F 280 M | EasyCut F 320 (2. Gen) | EasyCut F 320 (3. Gen) | EasyCut F 320 M (2. Gen) | EasyCut F 320 M (3. Gen) | EasyCut F 320 CV | EasyCut F 320 CR | EasyCut F 360 M | EasyCut F 360 CV | EasyCut F 360 CR | EasyCut F 400 Fold | EasyCut F 400 CV Fold | EasyCut F 400 CR | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Work width (m) | 2.71 | 2.73 | 3.14 | 3.14 | 3.16 | 3.16 | 3.16 | 3.16 | 3.60 | 3.60 | 3.60 | 4.04 | 4.04 | 4.04 |

configure

|

| PUSH design | series | series | series | series | series | series | series | series | series | series | series | - | - | - |

configure

|

| PULL design | - | - | - | optional | - | optional | optional | optional | optional | optional | optional | series | series | series |

configure

|

| No. of discs | 4 | 4 / 2 optional | 5 | 5 | 5 / 2 optional | 5 | 5 | 5 | 6 | 6 | 6 | 5 | 5 | 5 |

configure

|

| No. of top hats | 2 | 2 / 4 optional | 2 | 2 | 2 / 4 optional | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

configure

|

| Conditioner | - | - | - | - | - | - | series | - | - | series | - | - | series | - |

configure

|

| CR conditioner with rubber rollers | - | - | - | - | - | - | - | series | - | - | series | - | - | series |

configure

|

| Power requirement kW/hp | 44 / 60 | 40 / 55 | 51 / 70 | 51 / 70 | 48 / 65 | 51 / 70 | 59 / 80 | 59 / 80 | 51 / 70 | 66 / 90 | 90 / 90 | 74 / 100 | 74 / 100 | 74 / 100 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)

![[Translate to EN (US):]](/fileadmin/_processed_/1/9/csm_A001C1039_240428_PF13_250528_f834add98a.jpg)

![[Translate to EN (US):]](/fileadmin/_processed_/6/8/csm_DJI_20250430115716_0196_D_AK_277123_add5cf2d5b.jpg)

![[Translate to EN (US):]](/fileadmin/_processed_/0/9/csm_DJI_20250430125450_0203_D_AK_277372_128a6c5275.jpg)