The ComPack Pro from KRONE is equipped with several reinforced components, making this machine particularly suitable for successful continuous operation under extreme conditions and ensuring a long baling life.

- Semi or fully variable bale chamber

- Camless EasyFlow pick-up with w-line tines for less wear and effective gathering

- The Hardox cutting rotor with 530 mm diameter for maximum throughputs

- The precision cutting system delivers a smooth and precise cut

- Reinforced NovoGrip slat and belt conveyor for perfect bale roll and densities in any crop

- Net wrap or peripheral film wrap

- Wrapping unit – up to 36rpm for maximum efficiency

- Easy and fast servicing thanks to central lubrication

ComPack Pro

The comfortable all-rounder

KRONE is now introducing a technically updated round baler – the ComPack Pro. This machine, based on the well-known Comprima Plus, is equipped with new features that make it the ideal all-rounder for agricultural operations and contractors when it comes to power and comfort. Among other things, the new user interface for the terminal, state-of-the-art digital cameras and the precisely controllable silage additives unit, make it stand out. The facelift is rounded off with a new super modern design.

Read the news

The KRONE NovoGrip belt-and-slat elevator

NovoGrip is an endless slat conveyor, with rubber fabric belts, which forms the crop into solid, stable bales. All NovoGrip components in the ComPack Pro balers are designed to be particularly stable. NovoGrip is extremely resilient, performs well even in the heaviest silage and is also extremely durable.

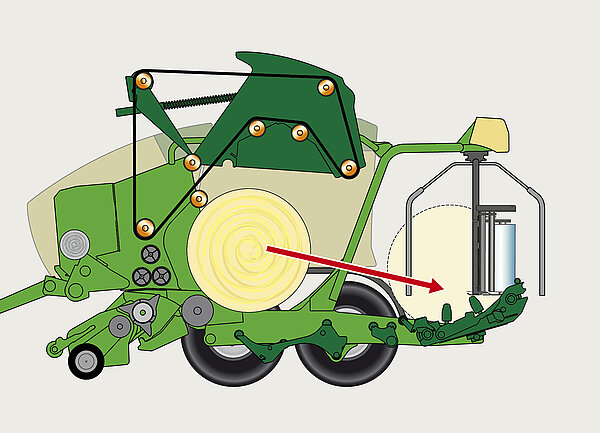

The ComPack Pro with semi-variable bale chamber

The ComPack F and CF Pro from KRONE are fixed chamber balers with a semi-variable bale chamber. They can be used to bale highly compacted and dimensionally stable bales in six different diameters. Built from heavy-duty components they are extremely solid and sturdy. They are also very cost-effective and exceptionally easy to operate and service – thanks to their uncluttered build and design.

Product features

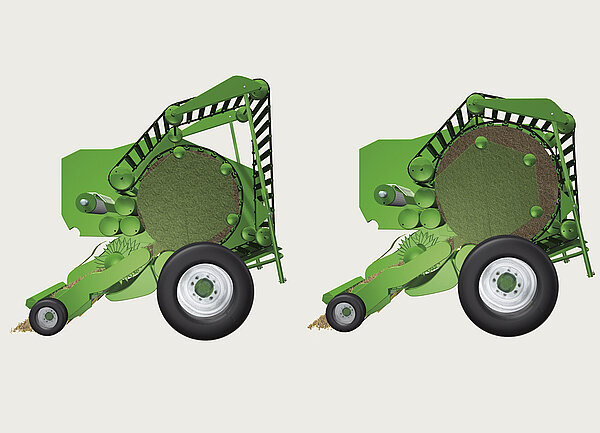

After the bale chamber opens the bale is transferred to the wrapping table by a lever. Activated only after the gauge roller senses a high weight, this lever transfers the bale safely to the wrapping table.

In addition to the technical details of the ComPack F Pro, the ComPack CF 155 XC Pro combination baler and wrapper features a powerful double-arm wrapper with a rotation speed of up to 36 rpm. With its deep trough and large side guide rolls, the wrapping table ensures that the bale is driven reliably during the wrapping process, even under difficult operating conditions. The table can also be used for discharging the bales in pairs.

The ComPack F 155 XC Pro can produce bales with a diameter of 1.25 m to 1.50 m. Operators simply set the required bale diameter in 5 cm increments on an easy-to-use system. The semi-variable bale chamber produces a softer and very small core – also in large-diameter bales. This gives the bales a great density, helps them retain their shape and makes them heavier.

[Translate to EN:] Die ComPack F 155 XC Pro kann Ballen mit 1,25 m bis 1,50 m Durchmesser pressen. Mit einer einfach zu bedienenden Steckerverstellung wird der gewünschte Ballendurchmesser in 5-cm-Schritten vorgewählt. Die semivariable Ballenkammer erzeugt auch bei großem Ballendurchmesser stets einen sehr kleinen weicheren Kern. Dadurch sind die Ballen sehr dicht, formstabil und schwer.

The operator simply enters the pressure, the diameter, and the number of film and net wraps. Once this is done, the combination will go about its business fully automatically. The bale is transferred to the wrapping table by a lever – the bale lifter.

The ComPack CV 150 XC Pro is equipped with a powerful double wrapper with a rotation speed of up to 36 rpm. The deep trough and the large guide rolls on the side of the wrapping table ensure that the bale is driven evenly during wrapping, even under difficult operating conditions.

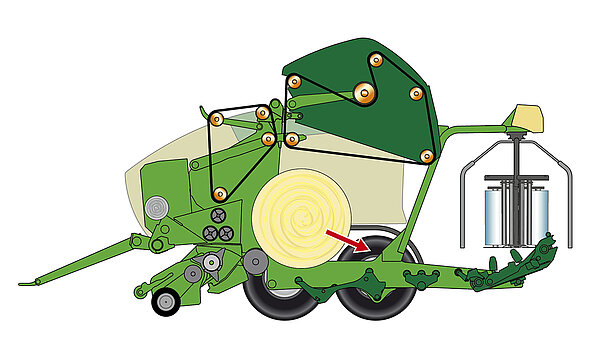

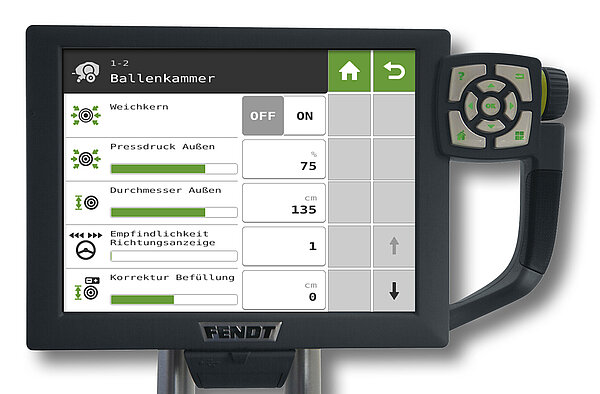

The ComPack allows the baling density to be infinitely adjusted in three zones directly from the terminal. The belt tension can be used to achieve different baling pressures in the various bale areas. This ensures that the bales are optimally baled for their intended use – for example, with maximum density for long transport distances or with a soft core for subsequent drying.

The bale diameter is measured by an angle sensor on the tensioning arm and the information is fed to the operator terminal so you can change the setting from the cab. The increasing pressure on the elevator ensures a uniform bale density.

The ComPack V 150 XC Pro with variable bale chamber allows the driver to infinitely adjust the desired bale diameter from 1.00 m to 1.50 m on the operating terminal in the tractor cabin. This significantly expands its range of applications. Smaller bale sizes are often preferred in silage whereas larger bales are more typical in hay and straw.

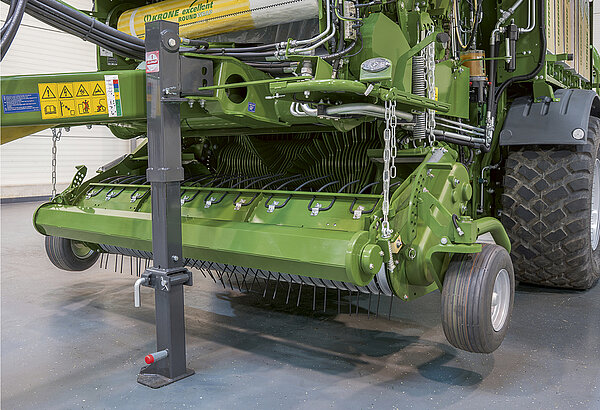

The EasyFlow pick-up is guided by two small side-mounted gauge wheels. Its height is changed by refitting a pin in a hole pattern. The guide wheels are castering and can pivot flexibly for The working height of the pick-up is set without tools in a hole pattern.

The crop press roller supports the work of the pick-up by detecting the size of the swath and preparing it for effective gathering. Its height is adjusted easily to adapt to the swath volume and ground speed.

The tines are 6 mm thick and have large-diameter coils – two properties that make them particularly resistant and hard-wearing. Arranged in five helical rows on the EasyFlow rotor and spaced at narrow 55 mm, they allow EasyFlow to pick up even short and heavy crops without losses.

KRONE has good reasons to opt against cam track control for the EasyFlow pick-up tines. Instead of using many moving parts that are prone to wear, KRONE prefers special strippers that ensure the angle and length of the tines is always correct.

The EasyFlow pick-up offers a 2.15 m work width for ultimate work rates. Its double tines are arranged in a W-line to reliably pick up even the widest swaths and feed the material in an extremely consistent flow to the rotor cutter. Thanks to the generous width it is not necessary to travel through very tight turns while the machine is baling. More than that, the pivoting and spring-loaded EasyFlow provides perfect ground contouring even in very rough terrain.

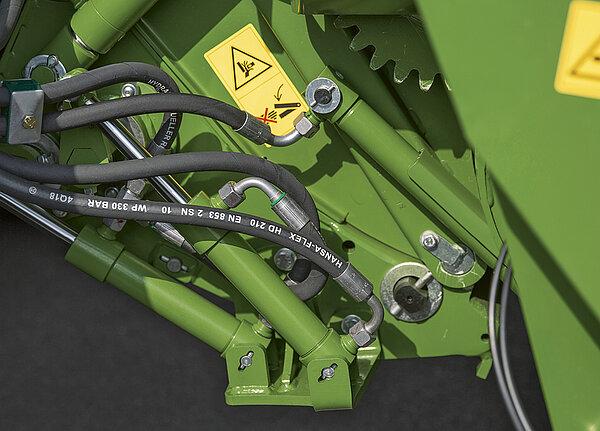

Machines featuring the hydraulic blade group control system extend and retract the blades hydraulically with appropriate control and precision. This ensures accurate control as they move into and out of the crop flow and is just another detail to optimize the overall performance of the machine.

The optional hydraulic blade group control system is operated from the tractor seat and offers additional convenience. Its use significantly reduces the time required to change the cutting length.

The standard manual control is a long lever that takes little effort to operate. This way you can quickly adjust the number of blades to varying conditions and customer needs.

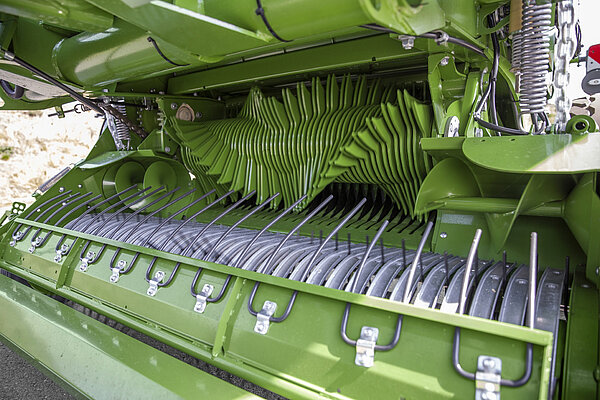

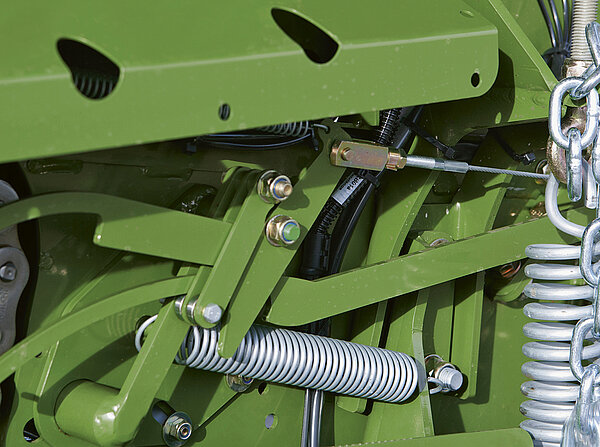

The blades are protected from damage by spring locks. break back when hitting an object and then resume their working position automatically after the object has passed, a system that results in dependable and high-quality cuts.

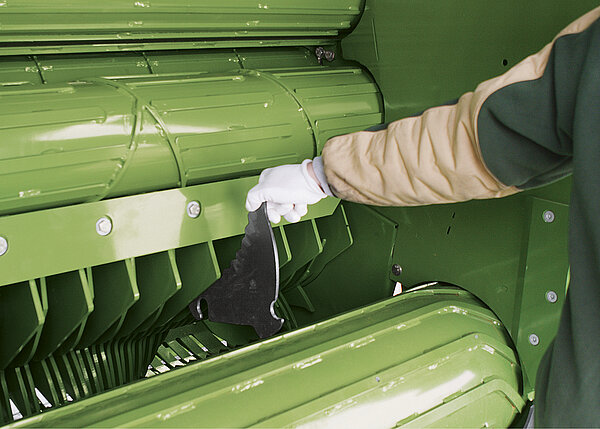

To fit or remove the blades, simply lower the blade cassette. To unlock the blades, all springs on the single blade locking device are released in one operation. and remove the blades conveniently from above.

The blades have long, curved cutting edges, which give particularly fuel-efficient cuts as the grass is pulled past them. Their wavy edges cut all forage types precisely and stay sharp longer. All blades in the cassette are identical and interchangeable.

Depending on the required length of cut, the blade cassette of the XCut cutting system has a maximum of 17 or 26 blades. When 8, 9 or 17 blades are in working position, the nominal chop length is 128 mm or 64 mm whereas the use of 13 or 26 blades reduces the chop length to 84 mm or 42 mm.

The cutting rotor is powered by oversize spur wheels which cope with the highest possible loads. They provide the rotor with the most dependable drive even in less than uniform swaths.

The cutting rotor is powered by oversize spur wheels which cope with the highest possible loads. They provide the rotor with the most dependable drive even in less than uniform swaths.

Should the feed chamber block up in difficult conditions, the operator simply lowers and raises the blade cassette hydraulically to remove the blockage. If the unit is specified with hydraulic blade group control, the blades will also be retracted automatically to clear the chamber and allow the crop to flow again.

Should the feed chamber block up in difficult conditions, the operator simply lowers and raises the blade cassette hydraulically to remove the blockage. If the unit is specified with hydraulic blade group control, the blades will also be retracted automatically to clear the chamber and allow the crop to flow again.

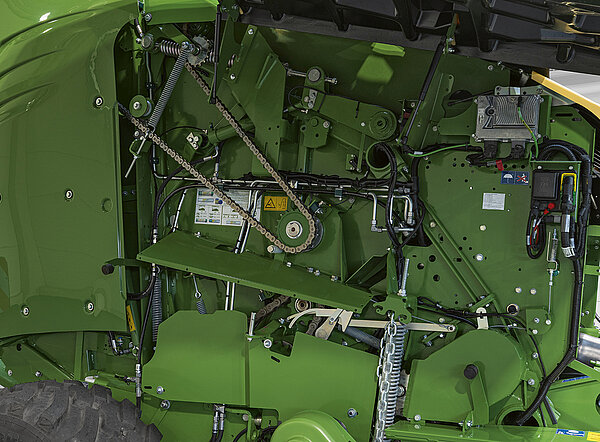

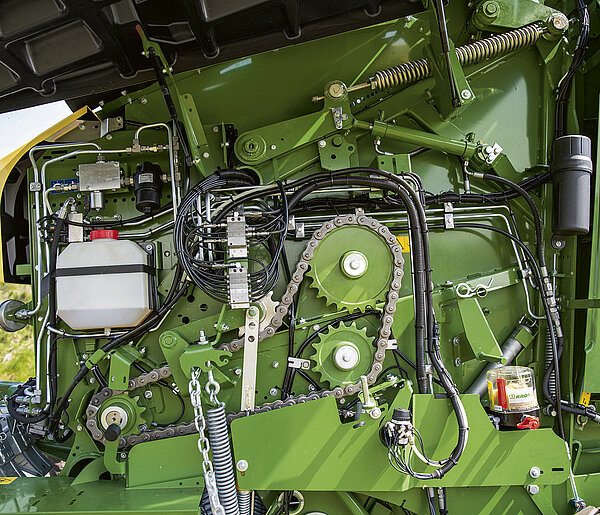

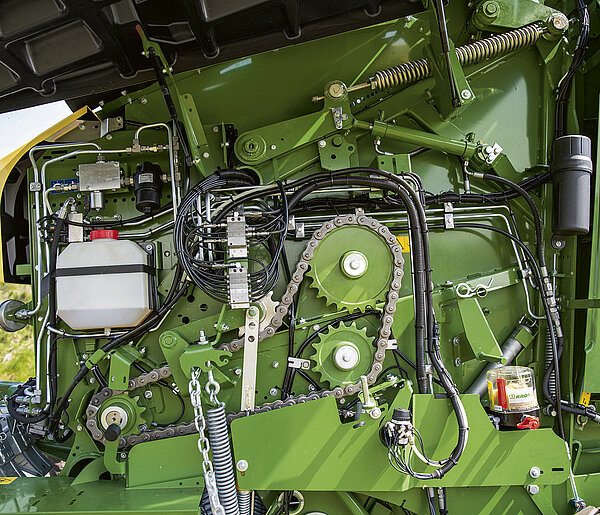

The strong 1½-inch chains withstand any strain. Spring-loaded chain tensioners and auto lubrication and greasing reduce service and maintenance and extend chain life. Controlled by a flow meter, the chain oil is applied at just the proper rate.

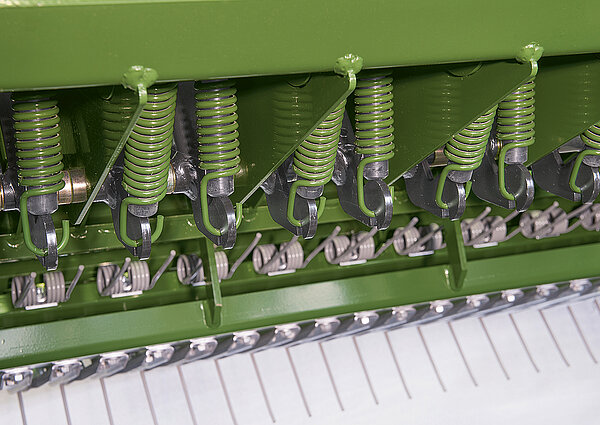

The core of a NovoGrip belt is made up of tear-resistant layers of plastic and fabric to which two layers of rubber lugs are vulcanized. This particular design accounts for the unique strength, elasticity, and longevity of these belts.

The core of a NovoGrip belt is made up of tear-resistant layers of plastic and fabric to which two layers of rubber lugs are vulcanized. This particular design accounts for the unique strength, elasticity, and longevity of these belts.

The robust and endless rubber fabric belts with metal slats achieve unsurpassed baling densities. The system relies on an extremely high tension of the belts that effectively transfers the drive power to the bale. The slat holders mount well protected between the rubber lugs and are bolted in bushes for great durability.

Thanks its special design, the NovoGrip belt-and-slat elevator suits all types of crops – straw and hay, wilted material and wet silage, performing reliably in all these conditions and treating the crop gently as the slats mesh with the bale for maximum densities and effective bale roll.

The wrapping material brake and the spreading bracket ensure an effective and full-cover wrapping of the bale.

After the net or film is applied, the knife cuts the material automatically and across the full width.

The tying unit always applies the net or film across the full width of the bale and covers its edges, saving time and resources. The net or film covers the edges of the bale for effective protection from rain.

The wrapping unit is at the front end of the machine for perfect visual control of the wrapping process. For inserting the wrapping material, the operator stands in front of the machine. The roll is pushed onto the swivelled-out locating shaft and next moved towards the tying unit. The storage compartment above the shaft stores up to two spare rolls of wrapping material.

The net wrapping is standard specification but you can also opt for base coat of film wrapping. This type of stretch film, which runs 1.28 m wide and is adhesive on one side, increases the quality of silage bales, because it exerts a greater pressure on the outer layers of the bale, reducing the amount of air trapped in it and making it easier to break up on the feeding floor.

If not used for wrapping, the table can be used for depositing the bales in pairs, which leads to great time savings in clearing the field.

The rubber mat is standard specification and protects the film from damage as it is placed on the ground. Equipped with a roll, the optional bale turner turns the bale gently on its face. It does not need to be removed it is not required: simply fold it away close to the wrapping table.

On account of the constantly increasing tractor power and the resulting sufficient oil volumes, the ComPack Pro balers are supplied with oil from the tractor as required via Load Sensing. This results in high efficiency and contributes to fast bale transfer and wrapping.

The film cutters provide extreme functional safety. You cut the film with the scissors. This direct way of cutting eliminates lose film ends.

There are two large film roll compartments on either side of the machine which store up 12 spare rolls of film, protecting them from rain and dust. Powerful LED lights are also available as an option in this area. The film roll holders roll holders fold down for convenient removal and refills.

The dispenser stretches the film to a 50% or 70% pre-stretch, depending on the gearwheel pairing of the drive. This ensures the bale density is maintained and the film is used efficiently. The dispenser has integrated film break detection relying on sensors that detect magnetic fields. When the system detects a film break, it shuts off the defective roll and wrapping continues with only the other dispenser in action.

The button on the ladder to the wrapping device makes it easy to operate the lifter, wrapping device, wrapping table, film shears and tailgate. This ensures uncomplicated film changes and also makes cleaning easier.

The wrapper takes 75 cm wide film material The number of wrapping layers (4, 6, 8 or 10) is preselected on the operating terminal.

In line with the high throughput of the baling and tying unit, the ComPack Pro wrapping device has a powerful double-arm wrapper. With a rotational speed of up to 36 rpm, wrapping is completed in no time at all, offering outstanding performance.

After the bale is finished, the bale chamber opens and the bale rolls on the gauge roller. As this senses the weight, it triggers the bale lifter which transfers the bale safely to the wrapping table. The system ensures a reliable bale transfer also on slopes.

The wrapping table of the ComPack Pro has large, side-mounted guide rolls and a deep trough. This gives the bales excellent lateral guidance during wrapping or feeding onto the wrapping table, ideal when working on slopes. A bale weighing system can be integrated in the table as an option. The system logs the individual and total bale weights and displays the readings on the in-cab screen.

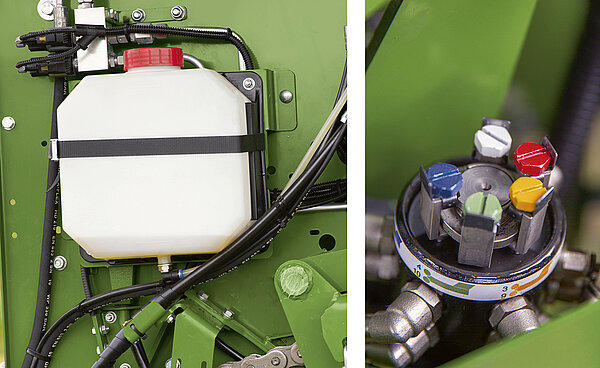

The optional, fully integrated silage additives unit for the KRONE ComPack allows the silage process to be optimised in a targeted manner. Two tanks of 110 litres each are available for different agents. The dosing rate can be controlled either by throughput, bale weight, moisture or time – even individually for each bale. The unit switches off automatically during the tying cycle.

All ComPack Pro models are equipped with a central lubrication unit as standard. The lubrication lines, which converge in a distributor block, are automatically filled with grease from a central grease reservoir and therefore supply the individual lubrication points as required. The system makes sure all nipples get the necessary attention, including those that are difficult to get at – a detail that helps eliminate potential downtime. The central lubrication system minimises maintenance work and at the same time increases the reliability and service life of the machine.

The ComPack Pro uses heavy-duty spherical roller bearings with improved sealing. These are lubricated via the central lubrication unit. for long service life.

The side panels open wide offering easy access to all drives, components and assemblies. Servicing the machine is fast and safe also at night, thanks to the LED lights under the side panels. Furthermore, LED lights around the chamber net/film unit make working at night also as easy as during the day.

A central chain lubrication system with piston pump and large reservoir (7 litres) reduces maintenance costs. It makes the ComPack Pro even more reliable and economical. The oil volume of the central chain lubrication unit can be adjusted as required using a flow rate regulator.

The sprockets have large diameters to minimize the strain on the chain. This in combination with the automatic chain tensioner leads to a significant reduction of wear and thus to time and cost savings.

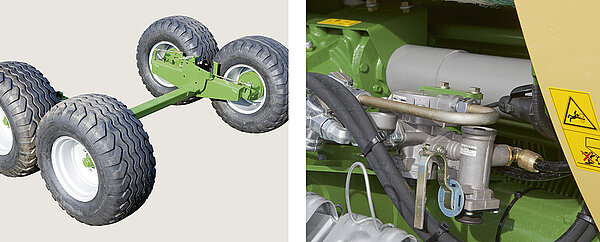

A tandem axle is standard specification on the CF and CV combination baler and wrappers and an option on the F and V models. Tandem axles offer greater tongue loads, smoother rides and better road stability. As they offer a larger contact area, they also reduce rutting and protect the soil. There are two different tyre sizes to choose from - 500/60 R 22.5 and 600/50 R 22.5.

The single axle is used only with ComPack F and V Pro. It can be fitted with two different flotation tyres. As standard, the tyres are available in size 500/50-17; 500/55-20 can be selected as an option.

A compressed air brake system is standard specification on both the single axle and tandem axle models. Export machines can also be equipped with a hydraulic brake.

Alternatively, the ComPack Pro can also be equipped with a ball-head attachment 80 for bottom hitching. It offers a high level of driving comfort, increases manoeuvrability and minimises wear.

The ComPack Pro comes as standard with a 40 mm drawbar eye for top and bottom hitching. A ratchet mechanism can be used to quickly adjust the drawbar to different hitching heights. In addition, three more hitch options are available to suit various needs in specific countries.

TIM (Tractor Implement Management) allows your machine to communicate with the tractor and control it. At this point the tractor is halted automatically too. After chamber film or net has been applied, the rear door opens, the bale is ejected and the door closes again. All the operator needs to do for starting the next cycle is pull off the tractor. TIM reduces operator fatigue, downtimes, fuel consumption and leads to more uniform bales and boosted productivity. The combi machines are equipped with TIM as standard, the solo machines as an option.

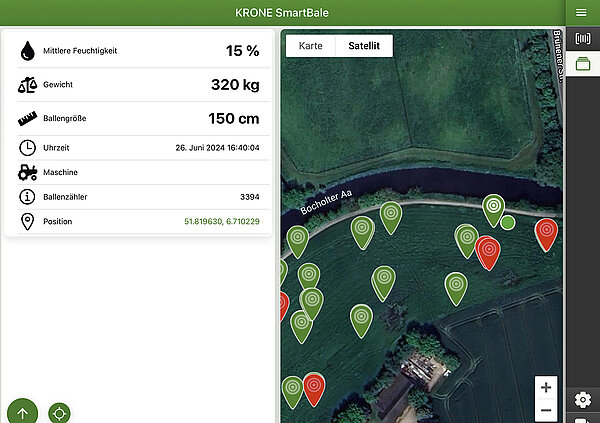

KRONE SmartBale displays all deposited round and square bales on a bale map. Depending on the baler equipment, the SmartBale app provides additional information such as moisture, weight, dimensions and whether the crops have been cut. Moist bales are colour-coded so that they can be easily identified and stored separately.

The optional SmartConnect telemetry unit enables the KRONE ComPack Pro to become a digital round baler. Each individual bale is automatically documented – including relevant machine data such as baling pressure, moisture content or GPS position. Real-time data transmission enables seamless tracking and creates the basis for precise evaluations and efficient operational management.

To improve visibility, KRONE round balers can be optionally equipped with digital cameras. A camera in the bale chamber allows the tying cycle to be monitored, while a second camera at the rear monitors the wrapping process or can be used as a rear-view camera. Changeover is automatic and event-controlled – to ensure maximum control and safety in every application. Can be ideally combined with the CCI terminals or the 7" monitor – to ensure perfect control in every situation.

The CCI 800 and CCI 1200 operating terminals have an 8" or 12" colour display with touch function. display the machine controls and camera footage side by side on the same screen. Both terminals are ISOBUS-compatible and therefore prepared for use with other machines.

The optional DS 500 operating terminal has a 5.7" colour display. Twelve function keys or the touchscreen can be used to adjust the values displayed there for the bale diameter, net layers and start of tying. The terminal also includes two bale counters, an operating hours counter and diagnostic functions for sensors and actuators.

The right model for every field of use

| ComPack F 155 XC | ComPack V 150 XC Pro | ComPack CF 155 XC Pro | ComPack CV 150 XC Pro | ||

|---|---|---|---|---|---|

| Bale dimensions (m, Ø x w) | 1.25 - 1.50 x 1.20 | 1.00 - 1.50 x 1.20 | 1.25 - 1.50 x 1.20 | 1.00 - 1.50 x 1.20 |

configure

|

| Bale Chamber | semi variable | variable | semi variable | variable |

configure

|

| Machine dimensions (m, l x w x h) | 4.70 x 2.61 x 3.15 | 4.99 x 2.61 x 2.99 | 7.17 x 2.97 x 3.40 | 7.66 x 2.97 x 2.99 |

configure

|

| Pick-up working width (m) | 2.15 | 2.15 | 2.15 | 2.15 |

configure

|

| Power requirement kW/hp | 51 / 70 | 51 / 70 | 74 / 100 | 74 / 100 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)