The powerful KRONE CombiPack HDP round baler is setting new standards when it comes to throughput. The high baling density and consistently uniform bale shape ensure continuously efficient operation over long periods of time. The innovative short cut cutting system enables the cutting length to be adjusted accurately, thus ensuring the optimum length is always achieved. Innovative operation, automated processes and maximum power ensure the efficiency and precision of the system. In addition, the quick changeover from net to film make it particularly convenient and versatile for processing all types of crops.

- Maximum throughput up to 30 per cent higher throughput

- Double twine tying system as standard for simple changeover directly in the cabin

- Net and film connection both systems process nets and films

- Spare blade drawer can be removed to side for safe and convenient access

- Laterally folding film roll store enables fast and easy roll replacement

- Low maintenance gearbox drive including optimum power transmission

- Triple drive system of the baling element guarantees reliable belt drive

CombiPack HDP

Baling and wrapping at the highest level

KRONE is setting new standards in terms of density, throughput, cutting lengths and maintenance with the CombiPack HDP CV 165 XC. The combination machine with integrated wrapping device produces very solid and dimensionally stable bales with variable diameters of 100 to 165 cm. Equipped with a cutting unit and a fully variable bale chamber with mono-belt, the machine can achieve extremely high bale densities and an increased throughput of more than 30%. The baling element and rotor are driven using the KRONE PowerDrive concept, which for the first time relies on a gearbox without any chains, thus reducing maintenance costs considerably. In a nutshell: an extremely efficient round baler for professional use.

Read the news

Profi-Rundballenpresse

KRONE CombiPack HDP

Weltneuheit: Die CombiPack HDP von KRONE ist die erste vollvariable Riemenpresse mit 41-Messer-Schneidwerk. Mit der neuen CombiPack HDP bringt KRONE eine extrem leistungsfähige und vielseitig einsetzbare Rundballenpresse auf den Markt, die nicht zuletzt dank exzellenter Schneid-, Press- und Wickeltechnik hinsichtlich Durchsatz und Ballendichte ein enorm hohes Level erreicht. Damit erweist sich die CombiPack HDP CV 165 XC als absolute Profi-Maschine für den Einsatz in allen Silagen und Trockengütern.

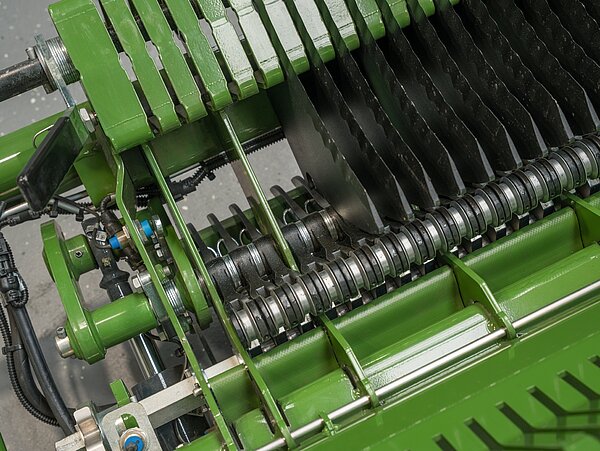

41 blades

The cutting unit of the KRONE CombiPack HDP is fitted with 41 blades, which means that a particularly short cutting length of 27 mm can be achieved. This not only improves the forage intake but also ensures the forage is more uniform as excess lengths are kept to a minimum. The efficient milling of the crops thus has a significant impact on the high forage quality and ensures uniform and optimum processing.

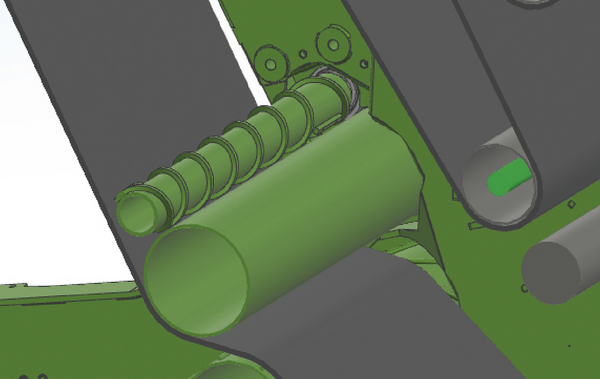

Well-designed drive concept

The CombiPack HDP is fitted with low maintenance and robust gearboxes that ensure reliable power transmission. The drive powers the main gearbox from the front where the power is then transmitted to another gearbox via a universal shaft. A laterally installed transfer gearbox directly transfers the power to a large cutting rotor. The belt drive rollers are also powered by a universal shaft. The triple drive of the baling element ensures a uniform rotation under all conditions. The well-designed drive concept ensures that the machine remains tidy. Oil lubrication is also not required thus preventing any soiling caused by oil.

Product features

The Load Sensing technology enables the CombiPack HDP to adjust the hydraulic oil pressure and flow rate to the requirements of the operating cycle thus ensuring maximum efficiency of all processes. This also preserves the tractor because it only has to pump hydraulic oil when it is actually required.

The CombiPack HDP drive system is designed to be highly durable. In conjunction with the automatic central lubrication, a maximum level of efficiency and minimal amount of wear is guaranteed, which in turn has a positive impact on the service life of the drive system and maintenance intervals. This enables running costs to be reduced and productivity to be increased.

The coupling of the CombiPack HDP is tried and tested up to a torque of 5000 NM ensuring the reliable and safe transmission of power. This high level of protection guarantees robust and stable operation even in challenging conditions. Downtimes can thus be minimised, which in turn contributes to the efficiency and profitability of the harvest.

The CombiPack HDP is fitted with low maintenance and robust gearboxes that ensure reliable power transmission. The drive powers the main gearbox from the front where the power is then transmitted to another gearbox via a universal shaft. A laterally installed transfer gearbox directly transfers the power to a large cutting rotor. The belt drive rollers are also powered by a universal shaft. The triple drive of the baling element ensures a uniform rotation under all conditions. The well-designed drive concept ensures that the machine remains tidy. Oil lubrication is also not required thus preventing any soiling caused by oil.

The endlessly wound mono belt ensures maximum power transmission thanks to the triple drive. Regardless of whether you are processing hay, straw or silage, this innovative drive concept rotates every crop material safely. Especially when working with damp crops, it reliably prevents the belt from slipping. This advanced technology not only contributes to the long life cycle and functionality of the machine, but also increases the reliability of the drive.

The bearing pressure of the crop press roller unit and pick-up can easily be set via the tension springs. The tool-free chain adjustment means that the working height of the crop press roller unit can be adapted quickly and easily to achieve maximum performance.

The centralised suspension of the EasyFlow pick-up ensures that the weight is distributed evenly so that it adapts optimally to uneven ground. The large oscillation radius of 140 mm levels out any uneven ground with the guide wheels ensuring an even and optimum intake.

The EasyFlow pick-up convinces with its uncontrolled design that comprises a few moveable parts and quiet operation, which in turn keeps wear to a minimum. This reduces maintenance and service costs.

The large crop press roller unit guarantees a continuous crop flow and prevents the forage from being pushed up in uneven swaths. The machine always operates at full power and at the maximum intake capacity ensuring an optimum forage intake.

The EasyFlow pick-up with five rows of tines convinces with its accurate and careful intake of crops. It is driven by a reliably protected hydraulic motor which is installed directly in the pick-up and protected against overload. The drive enables a greater working width, trouble-free pick-up at optimum driving speed and maximum intake capacity. With a generous working width of 2235 mm in accordance with DIN standards, the pick-up is perfect for wide swaths and guarantees the efficient processing of large harvesting volumes.

Blades are changed via the spare blade drawer that is provided as standard and can be pulled out of the left side of the machine. This makes it easy and convenient to change the blades and simple to clean.

In the event of a crop blockage in the feed channel, the blade cassette can be lowered hydraulically from the cabin so that blockages can be cleared quickly and easily. The crops are transferred directly into the bale chamber so that no material remains on the field.

The desired cutting length can be set quickly and easily via the central blade group control system. The blade is pre-selected directly on the cutting unit. Depending on the application conditions, the number of blades can be quickly and conveniently adjusted in five groups (41/21/20/5/0). When the spare blade drawer is lifted, the selected blades are reliably pressed into the working position through the slotted base – even if the blade slots are soiled.

The single blade locking device protects each individual blade against damage. If a blade encounters an obstruction, the spring enables it to avoid the obstruction and move downwards. The spring force then returns the blade to its original position. This increases the service life of the blades, thus resulting in lower maintenance costs and a higher level of efficiency.

The integral rotor reliably accepts the crops from the pick-up and guides them through the blades. The large, integrated augers reliably convey the material to the centre of the rotor ensuring the perfect cut. The minimal distance between the blade and tines ensures an accurate and effortless shear cut principle.

The cutting unit of the KRONE CombiPack HDP is fitted with 41 blades, which means that a particularly short cutting length of 27 mm can be achieved. This not only improves the forage intake but also ensures the forage is more uniform as excess lengths are kept to a minimum. The efficient milling of the crops thus has a significant impact on the high forage quality and ensures uniform and optimum processing.

Two cleaning rollers continuously clean the belt and deflection rolls. This permanently guarantees the reliable power transmission on to the belt for all crop materials.

The soft core setting can be used to adjust the firmness of the bale core individually in three zones. The pressure on the core is set in the terminal: A low value will produce a loose, soft core (particularly advantageous for hay), while a higher value produces a harder, compact core. The bale density is thus optimally adjusted to the crops, moisture and bale size.

The starter roller of the CombiPack HDP plays a deciding role when it comes to preparing the crops for the pressing process. It guarantees an even distribution and compression of the crops to achieve an optimum bale quality. The material is thus rotated as early as possible so that the bale is compressed from the outset.

The high-performance continuous belt installed in the bale chamber ensures that a particularly high bale density and uniform bale shape is achieved. The enclosed surface across the entire width almost completely prevents rolling losses. In addition, the mono belt convinces with its long service life and very quiet operation.

The fully variable bale chamber of the CombiPack HDP enables bales to be pressed with a diameter of 1.0 m to 1.65 m. The continuous setting on the terminal means that the required bale size can simply be adjusted. The baling force is optimally adjusted to the relevant harvest conditions to guarantee efficient and gentle baling and thus produce high-quality and dimensionally stable bales.

The CombiPack HDP guarantees an even distribution of the peripheral film across the entire bale width right over the edge. This guarantees a clean finish and reduces air pockets subsequently improving the forage quality and reducing rolling losses. The peripheral film also offers an improved level of surface protection thus stabilising the bale shape and enhancing the shelf life.

Inserting net and peripheral film is particularly convenient and ergonomic thanks to the net chute, provided as standard, and the hydraulically accessible insert position. The low insertion position makes the process considerably easier. To replace the roll of net or peripheral film, the tying system must be folded forwards and the net chute swung out to the side and front. The control panel on the side can be used to move the tying system into the relevant position to simplify the change. The net roll can then be pushed into the first or second wrapping material holder via a roll without having to be lifted – a fast, simple and efficient process. The wrapping and tying material can also be inserted from either the right or left side.

The CombiPack HDP is fitted with two tying systems, a key advantage when processing different crops such as silage and straw. The quick change from net to peripheral film is completed effortlessly directly from the tractor cabin, which noticeably improves productivity. The entire tying cycle can be conveniently controlled via the operating terminal.

If you do not want the bales to be wrapped, the wrapping table can be used for depositing the bales in pairs. Two bales can thus be deposited at once, which will significantly reduce the amount of time it takes to clear the field.

The control panel provided as standard on the rear side of the machine enables the simple control of all of the important functions directly on site. From the wrapping device to the holding and cutting device and bale transfer unit, everything can be operated easily and accurately. To make it even more convenient, the film magazine can be lowered so that reloading film can be completed quickly while sparing the operator's back.

The optional re-turning mode ensures that the bale is turned again on the wrapping table before it is ejected. During this process, air is pushed out from underneath the film, reducing the amount of oxygen and improving the forage quality. The bale mat provided as standard guarantees gentle depositing ensuring that the bale is not damaged by the chaff. The bale can optionally be deposited on the front side using a bale turner.

A 360° rotary position sensor monitors the rotation of the wrapping device and ensures the exact positioning and even film overlapping. If a film tear is detected, the driver receives an appropriate message on the terminal. The driver can then decide at the touch of a button whether the bale should just continue to be wrapped with one film roll or whether a new roll should be inserted. Only once this has been confirmed will the bale rotation be adjusted accordingly to guarantee a consistently high product quality and the best forage.

The wrapping arms of the CombiPack HDP provide fast and high-performance bale wrapping at a rotational speed of up to 40 rpm. Thanks to this high speed, the bale is already fully wrapped before the next bale has been fully pressed. The film pre-stretching can be easily adjusted between 55% and 70% to guarantee the best possible quality.

The wrapping table is fitted with four belts that form a deep trough and securely hold the bale in place. This design prevents any slipping or tilting, especially on steep surfaces. In addition, four guide rolls guarantee a smooth wrapping process, even on slopes.

The complete transfer cycle only takes 6 seconds. As soon as the bale chamber opens, the bale is actively placed on the wrapping table. A bale lifter underneath the bale ensures it is transferred safely, especially on slopes. The bale chamber closes again directly after the transfer to prepare the next bale.

The machine is fitted with a compressed air brake system as standard to ensure it is safe to drive on the road.

The CombiPack HDP relies on a large scale single axle that offers excellent manoeuvrability as well as maximum sward protection. The 650/65 R 26.5 size tyres provide a large contact surface guaranteeing minimal ground pressure, while the alternative 600/60 R 30.5 size tyres also offer outstanding slope stability. The 710/55 R 30.5 tyres are also available as an option. The generously dimensioned tyres preserve the sward even during tight turning manoeuvres and when reversing. At the same time, they prevent forage contamination and provide optimum traction on all terrains.

The hydraulically adjustable articulated drawbar also enables you to easily access entrances to fields that are tight and difficult to drive on. The articulated drawbar can be moved down fully so that net rolls can be changed easily. The height can conveniently be adjusted from the tractor cabin. An adjustable support jack is no longer required to connect and disconnect the machine.

The CombiPack HDP can be operated flexibly with a bottom or top hitching. Suitable couplings are available for every tractor. The optimised universal shaft design guarantees maximum power transmission regardless of which variant is selected.

TIM (Tractor Implement Management) allows your machine to communicate with the tractor and control it. At this point the tractor is halted automatically too. After chamber film or net has been applied, the rear door opens, the bale is ejected and the door closes again. All the operator needs to do for starting the next cycle is pull off the tractor. TIM reduces operator fatigue, downtimes, fuel consumption and leads to more uniform bales and boosted productivity.

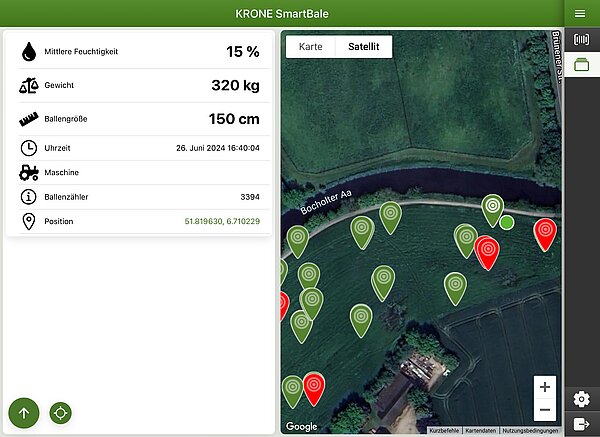

KRONE SmartBale displays all deposited round and square bales on a bale map. Depending on the baler equipment, the SmartBale app provides additional information such as moisture, weight, dimensions and whether the crops have been cut. Moist bales are colour-coded so that they can be easily identified and stored separately.

If the operating terminal on the tractor is ISOBUS compatible, it can be used to directly control the on-board electronic system of the CombiPack HDP. There is no need for an additional terminal, which also significantly simplifies operation.

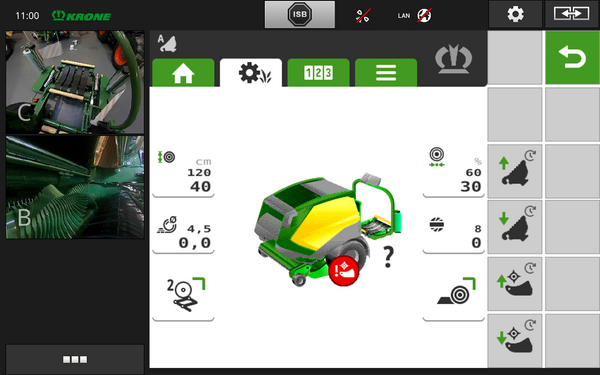

The CCI 800 and CCI 1200 operating terminals have an 8" or 12" colour display with touch function. display the machine controls and camera footage side by side on the same screen. Both terminals are ISOBUS-compatible and therefore prepared for use with other machines.

The DS 500 operating terminal with 5.7" colour display is available as an option and can either be operated via twelve function keys or a touchscreen. It provides the option of conveniently setting the relevant values, such as the bale diameter, net layers and start of the tying process. The terminal also includes several customer counters, two season counters, an operating hours counter and diagnostic functions for the sensors and actuators.

A robust gearbox reliably drives the baling belt and cutting unit – one oil change per year is sufficient. Only two chains are required to drive the baler and cleaning roller. This in turn reduces the amount of maintenance work to a minimum, so that no additional work is required throughout the season.

The CombiPack HDP is equipped with a central lubrication unit that reliably and evenly supplies all of the relevant components with lubricant. This reduces the required amount of maintenance work, extends the service life of the machine and ensures smooth operation even under the toughest conditions. The gear-assisted drive train ensures that the machine remains clean as no additional oil lubrication is required, guaranteeing maximum efficiency and minimal downtimes.

The working lights of the CombiPack HDP, that are provided as standard, ensure optimum visibility and increase operator comfort at all times of day and night. The areas around the pick-up, rotor, roll holder for reservoir rolls and wrapping table are specifically illuminated so that work can be completed accurately even in difficult light conditions. The LED maintenance lighting also illuminates the tying unit, the area underneath the side guards and the bale ejection tailgate. This ensures that any maintenance work and the bale handling process are even safer and more convenient.

CombiPack HDP

Vollvariable Press-Wickelkombination

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)