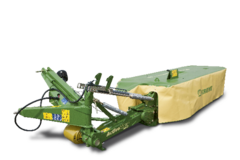

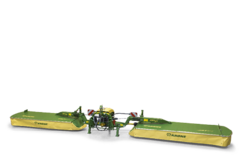

The EasyCut F model range is a line-up of innovative front mowers with or without tine or roller conditioner and work widths of 8'10.8" to 12' 3". At the same time, the range comprises particularly compact and light-weight front mowers for mountain fields and applications. Top hats are available for some models. These form narrow swaths that the tractor can straddle.

Product video

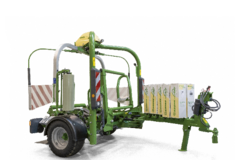

KRONE EasyCut F – Front-mounted disc mowers

The EasyCut F series includes innovative front mowers with working widths from 8' 10.8" to 11' 9.6", with optional tine or roller conditioner. The EasyCut M front mowers are our lightweight machines designed for operation on steep slopes and for spreading material across the work width. Their hitch points are configured to attach as well to small tractors for special applications.

Product features

- The EasyCut – The full product range

- SmartCut – SmartCut: Strip-free swaths from optimum blade overlaps

- Quick-change blades

- SafeCut – Individually protected cutting discs

- CV conditioner with V-shaped steel tines

- CR and M-Rolls conditioners with CR or polyurethane rollers

- EasyCut F 400 and F 400 CV with folding cutterbar as CV variant, or as merger auger variant

- EasyCut F 400 CR – Maximum efficiency and perfect forage conditioning

KRONE's EasyCut F models are front mounted mowers in a class of their own. Their innovative design makes them not only extremely durable and low-maintenance but also particularly flexible. Whether used as a solo machine or as a butterfly combination, the EasyCut F front mounted mowers ensure premium efficiency and reliability for your grass harvest.

- Working widths from 2.71 m to 4.04 m

- Cutterbar pushed (Push), pulled (Pull) or (Plus) with A-frame

- With or without conditioner

- Models with powered swath drum

- EasyCut F 400 and F 400 CV with optional folding cutterbar

The EasyCut F series comprises innovative front mounted mowers with working widths from 2.71 m to 4.04 m – optionally with tine or roller conditioners. Thanks to the choice of Push, Pull or Plus headstocks, the machines offer maximum flexibility for a wide range of operating conditions. Actively driven swath drums prevent the forage from being driven over and therefore ensure clean pick-up and the best forage quality.

- Fully welded cutterbar – Robust, sealed and permanently lubricated

- Durable satellite drive with large spur wheels – Very quiet running and optimum power transmission

- Without inner shoe for trouble-free mowing

The enclosed and fully welded cutterbar meets the highest quality standards and operates dependably and leak-free over many years of hard work. Massive and oil-immersed spur wheels impress by very quiet and reliable running in sustained peak-load operation.

- The wedge-shaped cutterbar guarantees clean cuts

- Heavy-duty spur gears run in widely-spaced double bearings

- Swathing or spreading depending on needs

The wedge-shaped cutterbar offers great flexibility to adjust through a large range of settings and leave a short stubble in meadows and pastures as well as long stubble in long-stemmed field crops. An EasyCut mower delivers a reliable performance and clean cut.

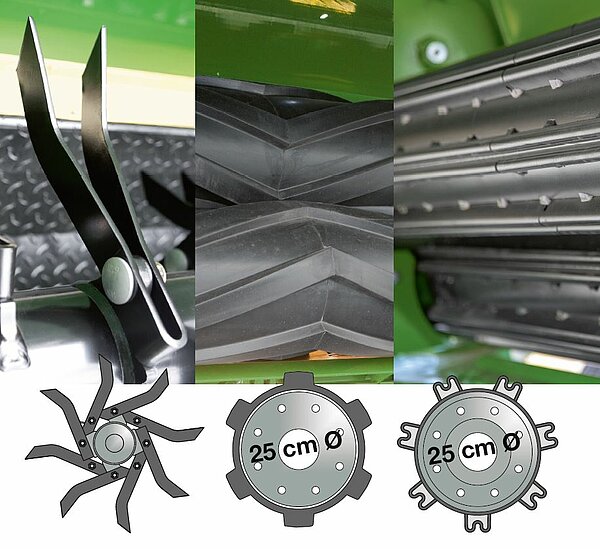

Quick-change blades allow operators to swap blades in the field quickly

Modular design of cutting discs

Minimal blade wear – 360° swivel range of the blades

Excellent cut thanks to KRONE SmartCut – Optimum overlap of the blade tracks

There are many reasons for choosing an EasyCut disc mower, including the quick-change blades, the inexpensive wear parts and the perfect arrangement of the cutting discs for stripe-free swaths.

- Full driveline protection for added reliability

- Neighbouring discs will not collide

- Wear-free

- Quick-change roll pins for minimum downtime and costs

Colliding discs may cause damage and involve costly repairs. KRONE SafeCut offers a maximum of protection and peace of mind. The award winning system on all EasyCut models offers a unique level of protection and operator comfort. SafeCut is part of the basic equipment of all EasyCut B series disc mowers.

- Close attachment to the tractor and compact on the road

- Adjustable bearing pressure

- Perfect contouring, three-dimensional pivoting

- SmartCut and SafeCut cutterbars

Attaching to the link arms without A-frame, the EasyCut PUSH models are light-weight and compact and have stretched guard cloths. All EasyCut cutterbars are permanently lubricated and feature SmartCut and SafeCut.

- For standard-fit hydraulic mower relief

- Convenient bering pressure adjustment from the cabin

- Perfect contouring from generous up- and rearward travel

- Front guards open wide for convenient maintenance

KRONE front mounted mowers with pulled cutterbar are the perfect machines to cut extremely undulating terrain. Whether cutting flat or hilly land, they stand out for their enormous agility and generous up- and rearward travel due to their pulled suspension.

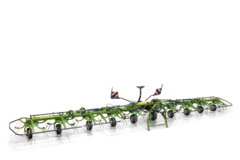

- Powered top hats present the swath between the tractor wheels

- Uniform swath presentation

- Continuous crop flow

The KRONE front mounted mower EasyCut F 280 has large swath drums. which mount behind the cutting discs on either end of the cutterbar. Driven from within the cutterbar, they provide a consistent flow of crop to the centre of the machine so that the tractor wheels will not run on the fluffy swath and the harvester will pick up the material without losses.

- Three headstock variants: Push, Pull or Plus with A-frame

- Modular design for easy configuration and retrofitting

- Telescopic top link for perfect ground tracking

- Bearing pressure adjustable without tools using springs or hydraulically (Pull)

- Optionally with large merger auger

The EasyCut F 320 and F 360 Gen. 4 stand for maximum flexibility and ease of use. Thanks to sophisticated technology, they can be tailored precisely to operational requirements. The compact design facilitates transport and handling – for efficient work in all conditions.

- Revised machine design with tightly tensioned guard cloths

- Folding front guard to change blades quickly

- Optional lighting system for improved road safety

- Hydraulically folding side guards for transport widths under 3.00 m

The EasyCut F 320 and F 360 Gen. 4 impress with their clear, practical design. Maintenance points are quickly accessible and transport details have been carefully thought out. Whether in the field or on the road, it's not just power that counts, but also comfort.

- Conditionneuse à dents CV – pour des temps courts de séchage dans le champ

- Commande facile et rapide

- Déflecteurs en option pour une dépose large

- Largeur d’andain réglable en continu

- Boîte de vitesses: Degré de conditionnement réglable

Le conditionneur à dents CV KRONE et ses dents en acier en forme de V, traitent le fourrage de façon intense sur toute la largeur du lamier. Le diamètre important de 64 cm et la disposition hélicoïdale des dents assurent un flux continu du fourrage, une capacité d’absorption élevée et un conditionnement optimal.

The CR roller conditioner models (polyurethane rollers or M-Rolls)

- Consistent crop flow by 25 cm diameter rollers

- High throughput from powered crop processor rollers

- Top quality from profiled rollers – thanks to their meshing effect

- Choice of roller conditioners – polyurethane rollers or steel M-Rolls

Leafy crops like Lucerne or clovers require a different type of conditioning than crops that are predominantly grass. The CR roller conditioners give particularly gentle treatment, leaving intact the delicate leaves which are so rich in protein and safeguarding the value of the feed. Spreading the crop will speed up wilting.

- Working width: 3.16 m

- With PUSH-type or PULL-type cutterbar

- Intensive conditioning: Choose between aggressive steel tines or chevron-profiled squeeze rollers

The front mounted mowers F 320 CV with tine conditioner and F 320 CR with roller conditioner are specialists that warrant high-quality forage. Featuring either a large 64 cm diameter tined rotor or two 25 cm squeeze rollers, these mowers are the pros that deliver high-quality forage and best conditioning even in high-yielding crops.

- 3.60 m work width, 3.45 m transport width

- Choose between aggressive steel tines or chevron-profiled rollers for intensive treatment

- Pushed or pulled design

The KRONE EasyCut F 360 CV and CR front mowers can have a pushed or pulled cutterbar. Working at a width of 3.60 m, the machine suits wide tractors with oversize tyres. More generous overlaps within the combination result in clean cuts on slopes and in curves and make for larger work widths in general.

- The first foldable cutterbar on the market

- 4.04 m working width

- Maximum overlap and high efficiency

- Hydraulic relief is as a standard feature

- EasyCut F 400 with standard merger auger

- EasyCut F 400 CV with tine conditioner

- Fold folding mechanism optional

- With Fold folding mechanism under 3 m transport width

This first foldable cutterbar on the market is awarded the DLG Silver Medal at Agritechnica 2019.

The KRONE development translates into maximum efficiency, maximum overlaps and maximum road safety. Directly from the tractor cabin, the operator activates a hydraulic slewing gear and swings the ends in front of the cutterbar. The EasyCut F 400 is available either with V-shaped steel tines as tine conditioner, or with merger auger.

The merger auger of KRONE's EasyCut F 400 Fold mower offers multiple advantages for forage harvesting: variable swath width, maximum forage quality and strip-free mowing thanks to great overlap. Combining it with other mower, e.g. the EasyCut B or EasyCut R models, allows for maximum overlap when driving around curves and working on slopes.

KRONE's innovative EasyCut F 400 Fold with merger auger sets new standards in forage harvesting. Depositing evenly formed swaths, the mower allows for efficient crop harvesting. A working width of more than four metres guarantees maximum efficiency – with a transport width of three metres made possible by the patented foldable cutterbar. Thus ensures excellent manoeuvrability for example when driving through cramped gates or unloading unto narrow forage tables.

The EasyCut F 400 CV Fold conditioner is equipped with durable V-shaped steel tines of robust design. The hard-wearing V-shaped steel tines can move out of the way of obstacles to reduce wear.

- Rigid cutterbar

- Perfect swathing between the tractor tyres

- Optional: hydraulically folding side guards

- Equipped with CR conditioner rollers as a standard | KRONE M-Rolls as an option

- Maximum acreage output

- Maximum efficiency when combined with other KRONE EasyCut mowers

The KRONE EasyCut F 400 CR mower with CR- or M-Roll conditioner rollers ensure perfect conditioning of the crops. Choose the hydraulically foldable guards on the sides (available as an option) for even more convenience.

Dairy farmers are looking into the potential of fresh grass for increasing milk yields from the basic ration. In view of rising silage storage costs, hay milk production programmes and further aspects fresh mass is being viewed from a different angle today. This new approach is supported by KRONE who offers the ideal machines that help you cut and feed highly valuable fodder every day. Combining the EasyCut F 400 CV Fold mower with the MX 330 GD forage wagon makes a powerful punch.

The foldable cutterbar of the KRONE EasyCut F 400 Fold makes working in cramped locations with bad visibility easier. Its transport width of less than 3 m ensures perfect handling, particularly when depositing the forage on narrow tables.

Immediately after depositing, the loading and forage transport wagon picks up the swaths cleanly and evenly before placing them loss-free on the forage table via the cross conveyor belt available ex works.

The merger auger deposits the crops in a compact, evenly shaped swath. This not only provided for quick, efficient harvesting but also ensures improved forage quality.

The perfect combination of KRONE machines: The EasyCut F 400 Fold front mounted mower with merger auger and the loading and forage transport wagon RX with 40 m3 loading volume constitute the KRONE Fresh Matter-Express, which stands for maximum efficiency and unsurpassed forage quality.

- Autonomous telemetry unit thanks to solar panel and rechargeable battery

- Automatic data acquisition in real time

- Data transmission to KRONE Smart Telematics and agrirouter

- Can be used flexibly on all machines (regardless of the manufacturer)

- Especially for machines without own electronics as well as rental machines

The KRONE SmartConnect Solar telemetry unit is completely autonomous thanks to the solar panel and rechargeable battery. This means that the box can be used flexibly on all machines, regardless of the manufacturer. The following data is sent by the SmartConnect Solar in real time: the position, the speed, active and inactive operating hours, the distance travelled, the working and transport position, the number of loads or the worked area and the charge status of the rechargeable battery. The machine data is recorded in real time and automatically transmitted to KRONE SmartTelematics or the agrirouter.

The right model for every field of use

| EasyCut F 280 | EasyCut F 280 M | EasyCut F 320 (2. Gen) | EasyCut F 320 (3. Gen) | EasyCut F 320 M (2. Gen) | EasyCut F 320 M (3. Gen) | EasyCut F 320 CV | EasyCut F 320 CR | EasyCut F 360 M | EasyCut F 360 CV | EasyCut F 360 CR | EasyCut F 400 Fold | EasyCut F 400 CV Fold | EasyCut F 400 CR | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working width (m) | 2.71 | 2.73 | 3.14 | 3.14 | 3.16 | 3.16 | 3.16 | 3.16 | 3.60 | 3.60 | 3.60 | 4.04 | 4.04 | 4.04 |

configure

|

| PUSH-type cutterbar (Push) | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | - | - | - |

configure

|

| PULL-type cutterbar (Pull) | - | - | - | optional | - | optional | optional | optional | optional | optional | optional | Standard | Standard | Standard |

configure

|

| No. of discs | 4 | 4 / 2 optional | 5 | 5 | 5 / 2 optional | 5 | 5 | 5 | 6 | 6 | 6 | 5 | 5 | 5 |

configure

|

| No. of top hats | 2 | 2 / 4 optional | 2 | 2 | 2 / 4 optional | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

configure

|

| Tine conditioner CV | - | - | - | - | - | - | Standard | - | - | Standard | - | - | Standard | - |

configure

|

| CR conditioner with rubber rollers | - | - | - | - | - | - | - | Standard | - | - | Standard | - | - | Standard |

configure

|

| Input power (kW/hp) | 44 / 60 | 40 / 55 | 51 / 70 | 51 / 70 | 48 / 65 | 51 / 70 | 59 / 80 | 59 / 80 | 51 / 70 | 66 / 90 | 90 / 90 | 74 / 100 | 74 / 100 | 74 / 100 |

configure

|

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

configure

|

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)