Mulching directly during the harvest

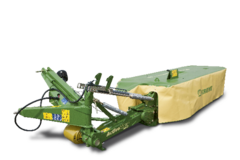

KRONE XCollect 750-2 RotoChop

KRONE now also offers the proven XCollect as a two-part maize header with integrated stubble mulcher. With the RotoChop, the crop can be harvested cleanly in just one pass and field hygiene improved at the same time.

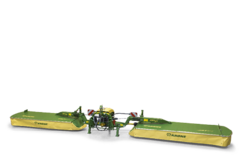

Spelle, Germany, September 2025: KRONE is expanding its successful XCollect series, first launched in 2018, with a three-part maize header and working widths from 6 to 9 m, by adding a model with a two-part design: The XCollect 750-2 (10 rows) with a working width of 7.5 m is equipped with an integrated mulcher that works the maize stubble intensively across the entire working width. This is a highly efficient way of abating increasing disease pressure caused by fungi and animal pests in just one work step.

Synergistic effects perfectly utilised

The new XCollect header utilises the synergistic effects of two different series. It merges the benefits of the XCollect’s unique collector principle, based on free cutting, with the straightforward two-part design of the proven EasyCollect, renowned for its exceptionally consistent crop flow.

A special feature of the XCollect is the separation of the cutting and conveying functions into two different processes. Cutting is performed by rotating, sickle-shaped cutting discs that are aligned horizontally. This means plants are cut with low levels of vibration and crop losses are minimised. The rotational speed and thus the cutting frequency can be easily adjusted to the individual crop and harvesting conditions via a switching stage in the drive train of the discs. The drive of the sickle discs is protected against overload by star ratchet clutches, and each individual disc is additionally protected by friction discs.

Proven technology for high-quality forage

The variable row harvesting according to the unique collector principle requires only low drive power. The maize stalks are pulled in lengthwise and then fed in a controlled manner to the pre-compression rollers and the chopper unit. The result: The lengthwise feed significantly reduces the proportion of excess length and creates the conditions for high-quality silage thanks to the improved chop quality.

The standard and infinitely variable adjustment of the collector speed also ensures that the maize plants are transferred evenly to the intake rollers under all operating conditions and with varying cutting lengths. This means that even lodged maize can be harvested without any significant losses. In addition, sensing skids on the harvesting header ensure that it adapts perfectly to the ground contours and that harvesting is completed perfectly, even on hilly terrain.

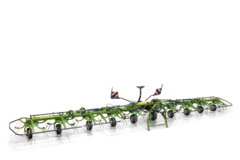

Combined harvesting and mulching for better field hygiene

The RotoChop mulching system integrated into the two-part XCollect maize header is new and unique. This mulching system allows the stubble to be worked across the entire working width in a single pass during the maize harvest before it is pressed into the soil by the tyres of the harvester and the following tractor/machine combinations. Further soil cultivation for subsequent crops is thus simplified. This not only saves time and fuel but above all benefits field hygiene. Since the flails of the mulcher break up the maize stubble to below the first joint of the stalk and accelerate the rotting process of the crop residues remaining in the field. This prevents the larvae of insect pests, such as the European corn borer, and spores of Fusarium fungi in particular from overwintering and subsequently reproducing.

The individual mulching units can be conveniently lifted and lowered hydraulically from the cab at the touch of a button. This is particularly helpful in temporarily changing ground conditions, such as tracks, or in wet conditions. If the mulchers are overloaded, for example by foreign objects, the corresponding mulching units are briefly lifted and then lowered again. If mulching is not required, the mulching unit, which is driven by a separate gearbox can simply be switched off and swivelled upwards.

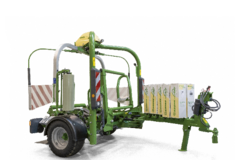

Integrated transport chassis for even more comfort

For road transport, the two lateral frames of the maize header can be folded in vertically to ensure that the transport width, including the mulcher, is only 3 m. An intelligent folding mechanism positions the mulching units in such a way that they are orientated with the narrow side facing the driver and always offer them a sufficiently large field of vision.

As an optional extra, KRONE offers a fully integrated hydraulic transport chassis for the XCollect. It reduces the load on the front axle of the harvester, facilitates approval for road use and improves driving comfort. Further, it eliminates the need to park a transport wagon, as the integrated transport chassis is lifted hydraulically during field work and can remain on the header. A fully integrated comfort front guard with lighting is also available as an optional extra. It ensures that you are always safe on the road.

Another advantage of the XCollect: The maize header is exceptionally easy to maintain. This is because large and easy-to-open covers offer optimum accessibility. The mulching tools are also easy and convenient to replace if necessary.

Conclusion: With the new two-part XCollect model and the integrated RotoChop mulching system, KRONE, as a header specialist, is expanding its range of maize headers, which are renowned worldwide for their high quality and comfort. The integrated mulching system, which improves field hygiene directly during the maize harvest, can be seen as a response to the globally increasing infestation pressure from insect pests and fungal diseases.

Quick read

- New model with integrated mulcher: KRONE is expanding the XCollect series with the two-part 750-2 model with 7.5 m working width and integrated RotoChop mulching system for simultaneous harvesting and mulching.

- Efficient field hygiene: The mulching system breaks up maize stubble to below the first stalk node, thus reducing the pressure caused by pests (e.g. European corn borer) and fungi (e.g. fusarium) directly during the harvest.

- Combination of proven systems: Combines the free cutting principle of the XCollect with the simple design of the EasyCollect providing an even crop flow and high cutting quality.

- Optimised cutting process: Sickle discs cut with low levels of vibration, minimise piston losses and are protected against overload by star ratchet clutches and friction discs.

- High-quality silage thanks to longitudinal intake: The row-independent harvesting with longitudinal feed reduces excess lengths and improves the chop quality – ideal for forage silage.

- Convenient controls: Mulching units are controlled hydraulically, automatically raised in the event of an overload and can be deactivated and swivelled up if required.

- Easy to transport: The lateral frame and mulcher can be folded compactly for road transport (transport width: 3 m). Optionally includes integrated running gear and front guard with lighting.

Press contact:

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935 188 20

markus.steinwendner@krone.de

www.krone-agriculture.com

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)