the comfortable all-rounder

ComPack Pro

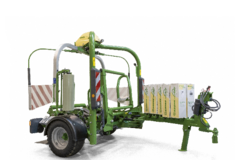

Compact, powerful and convenient – this makes the new ComPack Pro round baler from KRONE the ideal all-rounder.

Spelle, Germany, September 2025: KRONE is now introducing a technically updated round baler – the ComPack Pro. This machine, based on the well-known Comprima Plus, is equipped with new features that make it the ideal all-rounder for agricultural operations and contractors when it comes to power and comfort. Among other things, the new user interface for the terminal, state-of-the-art digital cameras and the precisely controllable silage additives unit, make it stand out. The facelift is rounded off with a new super modern design.

Four variants of the compact and robust ComPack Pro are available. Of the two solo machines ComPack F 155 XC Pro and V 150 XC Pro, the former has a semi-variable baling system with a diameter of 1.25 to 1.50 m, while the latter is a fully variable version that compacts bales with a diameter of 1.00 to 1.50 m. Both types are also available as ComPack CF 155 XC Pro and CV 150 XC Pro as well as combination balers and wrappers.

Clean collection and precise cut

The uncontrolled and winding EasyFlow pick-up collects the crops without loss and guides it evenly across the entire width to the cutting rotor. This ensures a perfect cutting pattern and low load peaks. With its spirally arranged tines, the XCut rotor cutting unit distributes the forage across the entire channel width right up to the edges, ensuring that the bale edges are always firm. The precision cutting unit is available with either 17 or 26 blades, which enable a theoretical cutting length of 64 or 42 mm. As the cutting unit can be switched in groups (17/8/9/0 or 26/13/13/0), the baler can adjust the cutting length flexibly, which is ideal for changing crops.<s> </s>

The blades are individually protected from foreign objects and can optionally be switched hydraulically from the cabin. A pressing-in device reliably brings the blades into working position.

Convenient operation and a clear overview

The tried and tested KRONE slat and belt conveyor system, which is characterised by its wide belts, strong chains and sprocket wheels is used as a baling element. The baling pressure of the V machines can be set from the tractor cabin. The driver can do this very quickly and conveniently using the new ISOBUS user interface. The states and processes of the machine can be displayed dynamically via the new user interface using animations and 3D graphics. Thanks to the optional digital cameras, two camera images can be displayed simultaneously. This enables all of the processes to be monitored perfectly.

All of the ComPack Pro machines are equipped with net wrapping as standard or with net and base coat film wrapping on request. There is a pivoting slide on the right side of the machine to make it easier to insert the rolls when replacing them.

Baling and wrapping perfectly combined

The ComPack Pro combination balers and wrappers are extremely efficient thanks to the double wrapping arm that operates at up to 36 rpm thus matching the high throughput of the baler. The bale is quickly and reliably transferred from the bale chamber to the wrapping table via a bale lifter. All of the necessary functions can be carried out via a control panel attached to the wrapping device. The momentary switches allow the lifter, wrapping device, wrapping table and film shears to be operated directly on the machine, which also makes it easier to change the films. For this purpose, the ComPack Pro carries up to 12 film rolls, which are protected under the storage compartments.

As an option, the combination baler and wrapper is also available with a fully integrated silage additives unit. Two tanks with a capacity of 120 litres each are available for this purpose. Dosing can be controlled flexibly according to the bale weight, moisture and time, or manually. The system is automatically switched off during the tying cycle.

The combination machines can also be equipped with a bale weighing device on request.

Practical helpers

All ComPack Pro machines are equipped with automatic oil and grease lubrication as standard. This means that the amount of maintenance work is kept to a minimum. There are also compressed air connections to clean the machine, which can be used to remove dust and dirt directly in the field.

Quick read:

- Versatile all-rounder: The ComPack Pro is available in four variants – two solo machines (F 155 XC Pro, V 150 XC Pro) and two combination balers and wrappers (CF 155 XC Pro, CV 150 XC Pro).

- Efficient forage intake: The EasyFlow pick-up ensures loss-free intake and uniform supply to the cutting rotor – for a clean cutting pattern and firm bale edge.

- Flexible cutting unit: XCut rotor cutting unit with 17 or 26 blades, can be switched in groups for variable cutting lengths depending on the crop.

- Convenient operation: New ISOBUS user interface with 3D graphics and animations, optionally with digital cameras for perfect process monitoring.

- Powerful combination balers and wrappers: Double wrapping arm operates at up to 36 rpm, fast bale transfer and intuitive operation directly on the wrapping device.

- Integrated silage agent dosing: Two 120-litre tanks, automatic switch-off during the tying cycle.

- Easy maintenance: Oil and grease lubrication as a standard feature, compressed air connections for cleaning.

Press contact:

Markus Steinwendner

Head of Marketing KRONE Agriculture

+49 5977 935 188 20

markus.steinwendner@krone.de

www.krone-agriculture.com

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/3/csm_Freisteller_KWT_468x468px_aec722e4d8.png)

![[Translate to EN:]](/fileadmin/_processed_/6/d/csm_ComPack_AK17649_275143_468_fc3b57f496.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/a/csm_CombiPACK__AK_270094_468px_e8c97eae1e.png)

![[Translate to EN:]](/fileadmin/_processed_/f/1/csm_VariPack_Pro__AK_269063_468px_23b96ff27c.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/8/csm_BiGPack_AK10841_280880_468px_116a7e307b.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/9/0/csm_KRONE_Freisteller_mit-schatten_468x468px2_bf6d5d115c.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/4/f/csm_RX_Freisteller_468x468px_6ecb398329.png)

![[Translate to EN (US):] [Translate to EN (US):]](/fileadmin/_processed_/0/a/csm_ZX_Freisteller_468x468px_cc1e39f93f.png)

![[Translate to EN:] [Translate to EN:]](/fileadmin/_processed_/5/7/csm_BiGM_KRONE_Freisteller_468x468px4_a92e7475bc.png)

![[Translate to EN (US):] Testname](/fileadmin/_processed_/4/7/csm_BiGX480_Freisteller_468x468px9_1017c2fa62.png)